Page 417 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 417

Be st Practice 7 .13 Lube, Seal and Control Oil System Best Practices

experience that travel indicators are not often supplied with the

valve. It is strongly recommended that valve travel indicators be

Body Port % Travel Valve Travel

supplied or retrofitted in the field.

size size (12.5%) (25.0%) (50%) (75%) (100%)

1/32" 1/16" 1/8" 3/16" ¼"

1'' 3/4 1.4 3.1 4.2 5.3 7.0 Bypass control

1'' 1'' 2.4 4.2 7.0 10.0 12

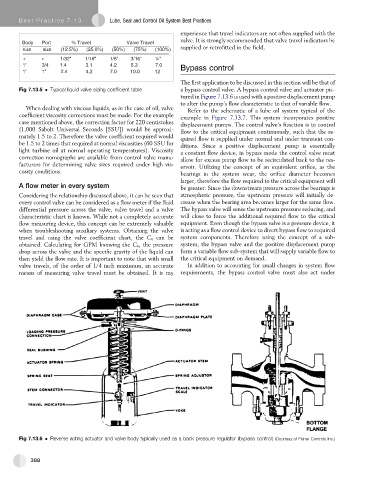

The first application to be discussed in this section will be that of

Fig 7.13.5 Typical liquid valve sizing coefficient table a bypass control valve. A bypass control valve and actuator pic-

tured in Figure 7.13.6 is used with a positive displacement pump

to alter the pump’s flow characteristic to that of variable flow.

When dealing with viscous liquids, as in the case of oil, valve

Refer to the schematic of a lube oil system typical of the

coefficient viscosity corrections must be made. For the example example in Figure 7.13.7. This system incorporates positive

case mentioned above, the correction factor for 220 centistokes displacement pumps. The control valve’s function is to control

(1,000 Sabolt Universal Seconds [SSU]) would be approxi- flow to the critical equipment continuously, such that the re-

mately 1.5 to 2. Therefore the valve coefficient required would quired flow is supplied under normal and under transient con-

be 1.5 to 2 times that required at normal viscosities (60 SSU for ditions. Since a positive displacement pump is essentially

light turbine oil at normal operating temperatures). Viscosity a constant flow device, in bypass mode the control valve must

correction nomographs are available from control valve manu- allow for excess pump flow to be recirculated back to the res-

facturers for determining valve sizes required under high vis- ervoir. Utilizing the concept of an equivalent orifice, as the

cosity conditions. bearings in the system wear, the orifice diameter becomes

larger, therefore the flow required to the critical equipment will

A flow meter in every system be greater. Since the downstream pressure across the bearings is

Considering the relationship discussed above, it can be seen that atmospheric pressure, the upstream pressure will initially de-

every control valve can be considered as a flow meter if the fluid crease when the bearing area becomes larger for the same flow.

differential pressure across the valve, valve travel and a valve The bypass valve will sense the upstream pressure reducing, and

characteristic chart is known. While not a completely accurate will close to force the additional required flow to the critical

flow measuring device, this concept can be extremely valuable equipment. Even though the bypass valve is a pressure device, it

when troubleshooting auxiliary systems. Obtaining the valve is acting as a flow control device to divert bypass flow to required

travel and using the valve coefficient chart, the C v can be system components. Therefore using the concept of a sub-

obtained. Calculating for GPM knowing the C v , the pressure system, the bypass valve and the positive displacement pump

drop across the valve and the specific gravity of the liquid can form a variable flow sub-system that will supply variable flow to

then yield the flow rate. It is important to note that with small the critical equipment on demand.

valve travels, of the order of 1/4 inch maximum, an accurate In addition to accounting for small changes in system flow

means of measuring valve travel must be obtained. It is my requirements, the bypass control valve must also act under

Fig 7.13.6 Reverse acting actuator and valve body typically used as a back pressure regulator (bypass control) (Courtesy of Fisher Controls Inc.)

388