Page 420 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 420

Lube, Seal and Control Oil System Best Practices Best Practice 7 .13

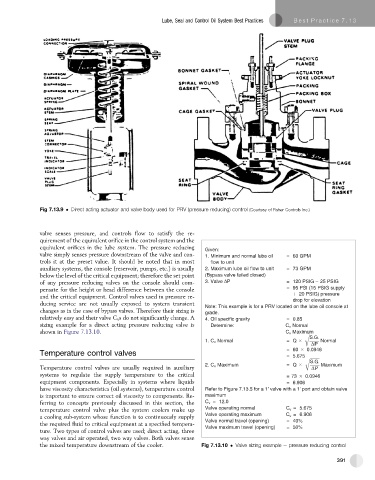

Fig 7.13.9 Direct acting actuator and valve body used for PRV (pressure reducing) control (Courtesy of Fisher Controls Inc.)

valve senses pressure, and controls flow to satisfy the re-

quirement of the equivalent orifice in the control system and the

equivalent orifices in the lube system. The pressure reducing

Given:

valve simply senses pressure downstream of the valve and con- 1. Minimum and normal lube oil = 60 GPM

trols it at the preset value. It should be noted that in most flow to unit

auxiliary systems, the console (reservoir, pumps, etc.) is usually 2. Maximum lube oil flow to unit = 73 GPM

below the level of the critical equipment; therefore the set point (Bypass valve failed closed)

of any pressure reducing valves on the console should com- 3. Valve P = 120 PSIG 25 PSIG

pensate for the height or head difference between the console = 95 PSI (15 PSIG supply

20 PSIG) pressure

and the critical equipment. Control valves used in pressure re- drop for elevation

ducing service are not usually exposed to system transient Note: This example is for a PRV located on the lube oil console at

changes as in the case of bypass valves. Therefore their sizing is grade.

relatively easy and their valve C v s do not significantly change. A 4. Oil specific gravity = 0.85

sizing example for a direct acting pressure reducing valve is D r e t e m n i : e C v Normal

shown in Figure 7.13.10. C v Maximum

S G

1. C v Normal = Q Normal

P P

= 60 0.0946

Temperature control valves = 5.675

G

2. C v Maximum = Q Maximum

Temperature control valves are usually required in auxiliary P

systems to regulate the supply temperature to the critical = 73 0.0946

equipment components. Especially in systems where liquids = 6.906

have viscosity characteristics (oil systems), temperature control Refer to Figure 7.13.5 for a 1' valve with a 1' port and obtain valve

is important to ensure correct oil viscosity to components. Re- maximum

ferring to concepts previously discussed in this section, the C v = 12.0

temperature control valve plus the system coolers make up Valve operating normal C v = 5.675

a cooling sub-system whose function is to continuously supply Valve operating maximum C v = 6.906

Valve normal travel (opening) = 40%

the required fluid to critical equipment at a specified tempera- Valve maximum travel (opening) = 50%

ture. Two types of control valves are used; direct acting, three

way valves and air operated, two way valves. Both valves sense

the mixed temperature downstream of the cooler. Fig 7.13.10 Valve sizing example e pressure reducing control

391