Page 427 - Subyek Teknik Mesin - Forsthoffers Best Practice Handbook for Rotating Machinery by William E Forsthoffer

P. 427

Be st Practice 7 .15 Lube, Seal and Control Oil System Best Practices

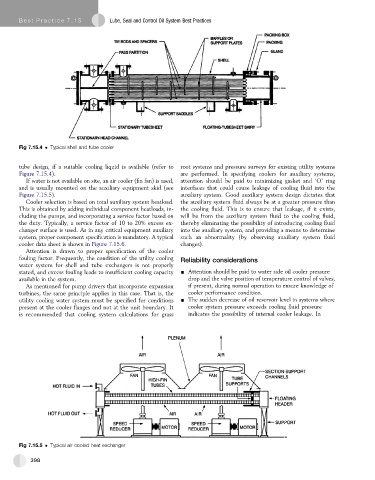

Fig 7.15.4 Typical shell and tube cooler

tube design, if a suitable cooling liquid is available (refer to root systems and pressure surveys for existing utility systems

Figure 7.15.4). are performed. In specifying coolers for auxiliary systems,

If water is not available on site, an air cooler (fin fan) is used, attention should be paid to minimizing gasket and ‘O’ ring

and is usually mounted on the auxiliary equipment skid (see interfaces that could cause leakage of cooling fluid into the

Figure 7.15.5). auxiliary system. Good auxiliary system design dictates that

Cooler selection is based on total auxiliary system heatload. the auxiliary system fluid always be at a greater pressure than

This is obtained by adding individual component heatloads, in- the cooling fluid. This is to ensure that leakage, if it exists,

cluding the pumps, and incorporating a service factor based on will be from the auxiliary system fluid to the cooling fluid,

the duty. Typically, a service factor of 10 to 20% excess ex- thereby eliminating the possibility of introducing cooling fluid

changer surface is used. As in any critical equipment auxiliary into the auxiliary system, and providing a means to determine

system, proper component specification is mandatory. A typical such an abnormality (by observing auxiliary system fluid

cooler data sheet is shown in Figure 7.15.6. changes).

Attention is drawn to proper specification of the cooler

fouling factor. Frequently, the condition of the utility cooling Reliability considerations

water system for shell and tube exchangers is not properly

stated, and excess fouling leads to insufficient cooling capacity - Attention should be paid to water side oil cooler pressure

available in the system. drop and the valve position of temperature control of valves,

As mentioned for pump drivers that incorporate expansion if present, during normal operation to ensure knowledge of

turbines, the same principle applies in this case. That is, the cooler performance condition.

utility cooling water system must be specified for conditions - The sudden decrease of oil reservoir level in systems where

present at the cooler flanges and not at the unit boundary. It cooler system pressure exceeds cooling fluid pressure

is recommended that cooling system calculations for grass indicates the possibility of internal cooler leakage. In

Fig 7.15.5 Typical air cooled heat exchanger

398