Page 325 - T. Anderson-Fracture Mechanics - Fundamentals and Applns.-CRC (2005)

P. 325

1656_C007.fm Page 305 Monday, May 23, 2005 5:54 PM

Fracture Toughness Testing of Metals 305

Each of the various fracture testing standards contains restrictions on fatigue loads, which are

designed to satisfy the above requirements. The precise guidelines depend on the nature of the test.

In K tests, for example, the maximum K during fatigue loading must be no greater than a particular

Ic

fraction of K . In J and CTOD tests, where the test specimen is typically fully plastic at failure,

Ic

the maximum fatigue load is defined as a fraction of the load at ligament yielding. Of course one

can always perform fatigue precracking well below the allowable loads in order to gain additional

assurance of the validity of the results, but the time required to produce the crack (i.e., the number

of cycles) increases rapidly with decreasing fatigue loads.

7.1.4 INSTRUMENTATION

At a minimum, the applied load and a characteristic displacement on the specimen must be measured

during a fracture toughness test. Additional instrumentation is applied to some specimens in order

to monitor the crack growth or to measure more than one displacement.

Measuring load during a conventional fracture toughness test is relatively straightforward, since

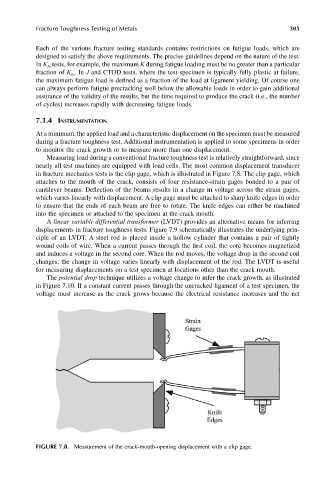

nearly all test machines are equipped with load cells. The most common displacement transducer

in fracture mechanics tests is the clip gage, which is illustrated in Figure 7.8. The clip gage, which

attaches to the mouth of the crack, consists of four resistance-strain gages bonded to a pair of

cantilever beams. Deflection of the beams results in a change in voltage across the strain gages,

which varies linearly with displacement. A clip gage must be attached to sharp knife edges in order

to ensure that the ends of each beam are free to rotate. The knife edges can either be machined

into the specimen or attached to the specimen at the crack mouth.

A linear variable differential transformer (LVDT) provides an alternative means for inferring

displacements in fracture toughness tests. Figure 7.9 schematically illustrates the underlying prin-

ciple of an LVDT. A steel rod is placed inside a hollow cylinder that contains a pair of tightly

wound coils of wire. When a current passes through the first coil, the core becomes magnetized

and induces a voltage in the second core. When the rod moves, the voltage drop in the second coil

changes; the change in voltage varies linearly with displacement of the rod. The LVDT is useful

for measuring displacements on a test specimen at locations other than the crack mouth.

The potential drop technique utilizes a voltage change to infer the crack growth, as illustrated

in Figure 7.10. If a constant current passes through the uncracked ligament of a test specimen, the

voltage must increase as the crack grows because the electrical resistance increases and the net

FIGURE 7.8. Measurement of the crack-mouth-opening displacement with a clip gage.