Page 328 - T. Anderson-Fracture Mechanics - Fundamentals and Applns.-CRC (2005)

P. 328

1656_C007.fm Page 308 Monday, May 23, 2005 5:54 PM

308 Fracture Mechanics: Fundamentals and Applications

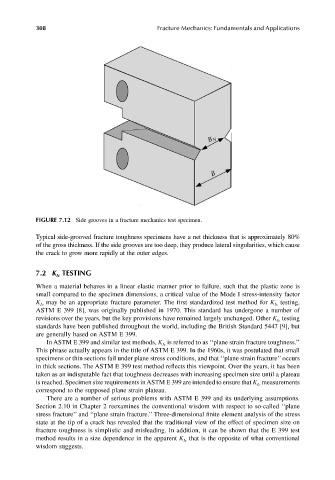

FIGURE 7.12 Side grooves in a fracture mechanics test specimen.

Typical side-grooved fracture toughness specimens have a net thickness that is approximately 80%

of the gross thickness. If the side grooves are too deep, they produce lateral singularities, which cause

the crack to grow more rapidly at the outer edges.

7.2 K TESTING

Ic

When a material behaves in a linear elastic manner prior to failure, such that the plastic zone is

small compared to the specimen dimensions, a critical value of the Mode I stress-intensity factor

K may be an appropriate fracture parameter. The first standardized test method for K testing,

Ic

Ic

ASTM E 399 [8], was originally published in 1970. This standard has undergone a number of

revisions over the years, but the key provisions have remained largely unchanged. Other K testing

Ic

standards have been published throughout the world, including the British Standard 5447 [9], but

are generally based on ASTM E 399.

In ASTM E 399 and similar test methods, K is referred to as ‘‘plane strain fracture toughness.’’

Ic

This phrase actually appears in the title of ASTM E 399. In the 1960s, it was postulated that small

specimens or thin sections fail under plane stress conditions, and that ‘‘plane strain fracture’’ occurs

in thick sections. The ASTM E 399 test method reflects this viewpoint. Over the years, it has been

taken as an indisputable fact that toughness decreases with increasing specimen size until a plateau

is reached. Specimen size requirements in ASTM E 399 are intended to ensure that K measurements

Ic

correspond to the supposed plane strain plateau.

There are a number of serious problems with ASTM E 399 and its underlying assumptions.

Section 2.10 in Chapter 2 reexamines the conventional wisdom with respect to so-called ‘‘plane

stress fracture’’ and ‘‘plane strain fracture.’’ Three-dimensional finite element analysis of the stress

state at the tip of a crack has revealed that the traditional view of the effect of specimen size on

fracture toughness is simplistic and misleading. In addition, it can be shown that the E 399 test

method results in a size dependence in the apparent K that is the opposite of what conventional

Ic

wisdom suggests.