Page 327 - T. Anderson-Fracture Mechanics - Fundamentals and Applns.-CRC (2005)

P. 327

1656_C007.fm Page 307 Monday, May 23, 2005 5:54 PM

Fracture Toughness Testing of Metals 307

(a)

(b)

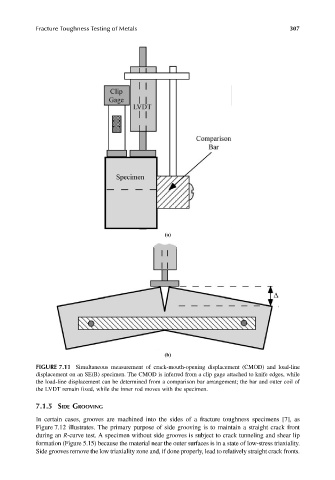

FIGURE 7.11 Simultaneous measurement of crack-mouth-opening displacement (CMOD) and load-line

displacement on an SE(B) specimen. The CMOD is inferred from a clip gage attached to knife edges, while

the load-line displacement can be determined from a comparison bar arrangement; the bar and outer coil of

the LVDT remain fixed, while the inner rod moves with the specimen.

7.1.5 SIDE GROOVING

In certain cases, grooves are machined into the sides of a fracture toughness specimens [7], as

Figure 7.12 illustrates. The primary purpose of side grooving is to maintain a straight crack front

during an R-curve test. A specimen without side grooves is subject to crack tunneling and shear lip

formation (Figure 5.15) because the material near the outer surfaces is in a state of low-stress triaxiality.

Side grooves remove the low triaxiality zone and, if done properly, lead to relatively straight crack fronts.