Page 120 - Fundamentals of Gas Shale Reservoirs

P. 120

100 PORE GEOMETRY IN GAS SHALE RESERVOIRS

0.0012 5.6.4 Scanning Electron microscopy

Micropores Mesopores Macropores The visual interpretation of mineralogy and porosity in PCM

0.001 PKM and CCM was conducted using two distinctive SEM imaging

Incremental volume (cm 3 /g) 0.0006 28 reveals quartz and clay particles as the dominant components

modes. SEM imaging, consisting of both SE and BSE images,

0.0008

of the shale (Fig. 5.22). These results are in agreement with

29

the XRD results. The images suggest that quartz is typically

found as large discrete particles intermixed with clay. The

clay particles are displayed as repeating layers of flat plate

0.0004

such as iron‐rich materials, are visible within the images and

0.0002 lets, typical of illite and/or kaolinite. Secondary minerals,

are typically highlighted during BSE imaging.

0

0.1 1 10 100 1000 5.6.5 Focused Ion beam/Scanning Electron

Pore width (nm)

microscopy

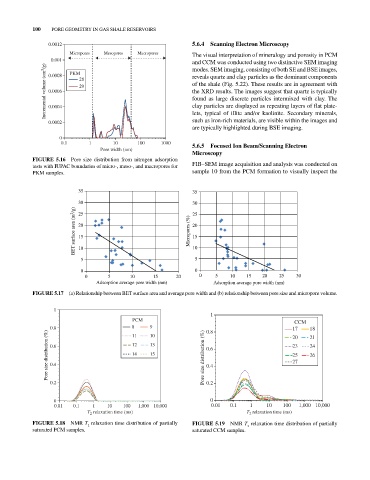

FIGurE 5.16 Pore size distribution from nitrogen adsorption

tests with IUPAC boundaries of micro‐, meso‐, and macropores for FIB–SEM image acquisition and analysis was conducted on

PKM samples. sample 10 from the PCM formation to visually inspect the

35 35

30 30

BET surface area (m 2 /g) 20 Micropores (%) 25

25

20

15

15

10

5 10 5

0 0

0 5 10 15 20 0 5 10 15 20 25 30

Adsorption average pore width (nm) Adsorption average pore width (nm)

FIGurE 5.17 (a) Relationship between BET surface area and average pore width and (b) relationship between pore size and micropore volume.

1

1

PCM CCM

0.8 8 11 9 10 0.8 17 18

Pore size distribution (%) 0.6 12 13 Pore size distribution (%) 0.6 23 24

21

20

15

14

25

26

27

0.4

0.4

0.2 0.2

0 0

0.01 0.1 1 10 100 1,000 10,000 0.01 0.1 1 10 100 1,000 10,000

T 2 relaxation time (ms) T 2 relaxation time (ms)

FIGurE 5.18 NMR T relaxation time distribution of partially FIGurE 5.19 NMR T relaxation time distribution of partially

2

2

saturated PCM samples. saturated CCM samples.