Page 165 - Fundamentals of Water Treatment Unit Processes : Physical, Chemical, and Biological

P. 165

120 Fundamentals of Water Treatment Unit Processes: Physical, Chemical, and Biological

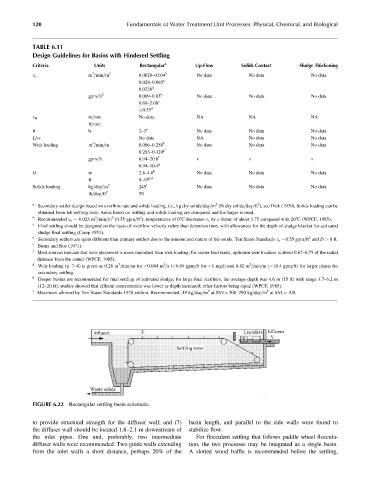

TABLE 6.11

Design Guidelines for Basins with Hindered Settling

Criteria Units Rectangular a Up-Flow Solids Contact Sludge Thickening

3

m =min=m 2 0.0028–0.034 b No data No data No data

v o

0.028–0.085 c

0.0226 d

gpm=ft 2 0.069–0.83 b No data No data No data

0.69–2.08 c

<0.55 d

v H m=min No data NA NA NA

ft=min

u h 2–3 e No data No data No data

L=w No data NA No data No data

3

Weir loading m =min=m 0.086–0.258 f No data No data No data

g

0.283–0.424

gpm=ft 6.94–20.8 f x x x

g

6.94–10.4

D m 2.4–4.6 h No data No data No data

ft 8–15 h,d

Solids loading kg=day=m 2 245 i No data No data No data

lb=day=ft 2 50

a 2 2

Secondary settler design based on overflow rate and solids loading, i.e., kg dry solids=day=m (lb dry solids=day=ft ), see Dick (1970). Solids loading can be

obtained from lab settling tests. Areas based on settling and solids loading are compared and the larger is used.

b 3 2 2

Recommended v o 0.023 m =min=m (0.55 gpm=ft ); temperatures of 08C decreases v s by a factor of about 1.75 compared with 208C (WPCF, 1985).

c

Final settling should be designed on the basis of overflow velocity rather than detention time, with allowances for the depth of sludge blanket for activated

sludge final settling (Camp 1953).

d 2

Secondary settlers are quite different than primary settlers due to the amount and nature of the solids. Ten States Standards v o ¼ 0.55 gpm=ft and D > 8 ft.

e

Burns and Roe (1971).

f

Most sources indicate that weir placement is more important than weir loading; for center feed tanks, optimum weir location is about 0.67–0.75 of the radial

distance from the center (WPCF, 1985).

g 3 3 3

Weir loading (p. 7–8) is given as 0.28 m =min=m for <0.044 m =s(<6.94 gpm=ft for <1 mgd) and 0.42 m =min=m(<10.4 gpm=ft) for larger plants for

secondary settling.

h

Deeper basins are recommended for final settling of activated sludge; for large final clarifiers, the average depth was 4.6 m (15 ft) with range 3.7–6.2 m

(12–20 ft); studies showed that effluent concentration was lower as depth increased; other factors being equal (WPCF, 1985).

i 2 2

Maximum allowed by Ten States Standards 1978 edition. Recommended: 49 kg=day=m at SVI ¼ 300–290 kg=day=m at SVI ¼ 100.

Influent Launders Effluent

Settling zone

Waste solids

FIGURE 6.22 Rectangular settling basin schematic.

to provide structural strength for the diffuser wall; and (7) basin length, and parallel to the side walls were found to

the diffuser wall should be located 1.8–2.1 m downstream of stabilize flow.

the inlet pipes. One and, preferably, two intermediate For flocculent settling that follows paddle wheel floccula-

diffuser walls were recommended. Two guide walls extending tion, the two processes may be integrated as a single basin.

from the inlet walls a short distance, perhaps 20% of the A slotted wood baffle is recommended before the settling,