Page 165 - Handbook of Battery Materials

P. 165

134 4 Electrochemistry of Manganese Oxides

4.2.5

Discharge Tests for Battery Materials

Testing various battery materials (MnO 2 ,MH, LiCoO 2 , etc.) requires a simple

and repeatable electrochemical test using 0.1–0.5 g of sample. Kozawa proposed

a plastic cell test [4] using a 100 mg MnO 2 sample mixed with a large amount of

graphite and discharging it at 1.0 mA. This method provides reproducible results for

open-circuit voltage (OCV), closed-circuit voltage (CCV), polarization, and capacity

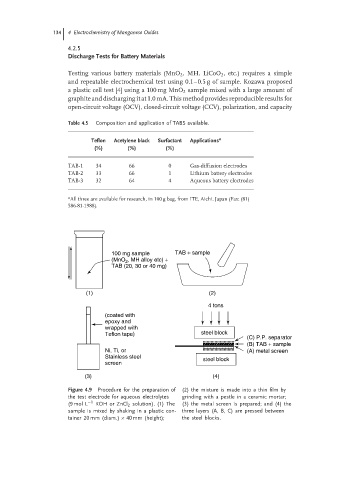

Table 4.5 Composition and application of TABS available.

Teflon Acetylene black Surfactant Applications a

(%) (%) (%)

TAB-1 34 66 0 Gas-diffusion electrodes

TAB-2 33 66 1 Lithium battery electrodes

TAB-3 32 64 4 Aqueous battery electrodes

a

All three are available for research, in 100 g bag, from ITE, Aichi. Japan (Fax: (81)

586-81-1988).

100 mg sample TAB + sample

(MnO 2 , MH alloy etc) +

TAB (20, 30 or 40 mg)

(1) (2)

4 tons

(coated with

epoxy and

wrapped with

Teflon tape) steel block

(C) P.P. separator

(B) TAB + sample

Ni, Ti, or (A) metal screen

Stainless steel steel block

screen

(3) (4)

Figure 4.9 Procedure for the preparation of (2) the mixtureismadeintoa thin filmby

the test electrode for aqueous electrolytes grinding with a pestle in a ceramic mortar;

(9 mol L −1 KOH or ZnCl 2 solution). (1) The (3) the metal screen is prepared; and (4) the

sample is mixed by shaking in a plastic con- three layers (A, B, C) are pressed between

tainer 20 mm (diam.) × 40 mm (height); the steel blocks.