Page 326 - Industrial Power Engineering and Applications Handbook

P. 326

Protection of electric motors la305

R- with an accuracy of less than 1 "C and a response time of

the order of 0.2 second. Pure metals possess almost a

Y-

linear temperature coefficient of resistance p, over a wide

B- range and this characteristic is used in monitoring the

temperature of a particular object. In pure platinum

N-

R, = ~ ~ + pe) 1sz

(

sw

where R, = resistance at temperature 8°C

Ro = resistance at 0°C = 100 Q

8 = end temperature "C

3 p = 3.85 x per "C at 0-100°C

G

The exact resistance variations of a P, - 100, RTD over

a range of temperatures are given in Table 12.2, and not

very different from those calculated by the above equation

and drawn in Figure 12.41.

Application

All the above sensing and monitoring devices are basically

supplements to overload and single-phasing protection.

They are worthwhile for critical installations that require

more accurate sensing or monitoring of the operating

temperatures of the different vital components or likely

-I hot spots. They also eliminate any chance of tripping for

I

M I all operating conditions that can be controlled externally.

55 "D A few applications may be speed variation, affecting

cooling at lower speeds, frequently varying loads, frequent

PTC

thermistors starts, stops, plugging and reversals etc. In all these cases,

the other protections may not detect the heating conditions

of the vital components of a machine as accurately as a

Tripping unit temperature detector.

12.8 Monitoring of a motor's actual

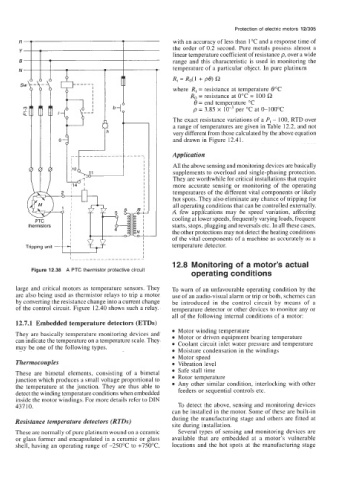

Figure 12.38 A PTC thermistor protective circuit

operating conditions

large and critical motors as temperature sensors. They To warn of an unfavourable operating condition by the

are also being used as thermistor relays to trip a motor use of an audio-visual alarm or trip or both, schemes can

by converting the resistance change into a current change be introduced in the control circuit by means of a

of the control circuit. Figure 12.40 shows such a relay. temperature detector or other devices to monitor any or

all of the following internal conditions of a motor:

12.7.1 Embedded temperature detectors (ETDs)

Motor winding temperature

They are basically temperature monitoring devices and Motor or driven equipment bearing temperature

can indicate the temperature on a temperature scale. They 0 Coolant circuit inlet water pressure and temperature

may be one of the following types.

Moisture condensation in the windings

Motor speed

Thermocouples Vibration level

These are bimetal elements, consisting of a bimetal Safe stall time

junction which produces a small voltage proportional to Rotor temperature

the temperature at the junction. They are thus able to Any other similar condition, interlocking with other

feeders or sequential controls etc.

detect the winding temperature conditions when embedded

inside the motor windings. For more details refer to DIN

43710. To detect the above, sensing and monitoring devices

can be installed in the motor. Some of these are built-in

Resistance temperature detectors (RTDs) during the manufacturing stage and others are fitted at

site during installation.

These are normally of pure platinum wound on a ceramic Several types of sensing and monitoring devices are

or glass former and encapsulated in a ceramic or glass available that are embedded at a motor's vulnerable

shell, having an operating range of -250°C to +750"C, locations and the hot spots at the manufacturing stage