Page 941 - Industrial Power Engineering and Applications Handbook

P. 941

Carrying power through metal-enclosed bus systems 28/891

28.9 Sample calculations for Continuous current rating 2500 A

designing a 2500 A non-isolated Ambient temperature 50°C

85°C

Maximum permissible operating temperature

phase aluminium busbar system Permissible final temperature at the end of the

fault 185°C

Example 28.12

Design parameters (A) Rectangular sections

Supply system three-phase four-wire 415 V ? IO%,

50 HZ ? 3% (i) Minimum size of busbars for short-circuit conditions

Fault level 45 kA The minimum size of busbars for an operating temperature

Duration of fault 1 second of 85°C and a final temperature of 185°C can be ascertained

from the curves of Figure 28.5, suggesting

870 r. 4 = 0.0799

A

f or A=-. 45 4i

0.0799

1

= 563.2 sq. mm

Maximum temperature rise of the busbars at the rated current

= 85 - 50

= 35°C

Assume the temperature of the busbars at the time of fault =

85°C and rectangular flats of electrolytic grade E-91 E or its

Insulator supporting equivalent. Busbars chosen for each phase - four (152.4

mm x 6.35 mm) - which are more than the minimum size

MS or aluminium required to account for the thermal effects during a short

enclosure circuit condition

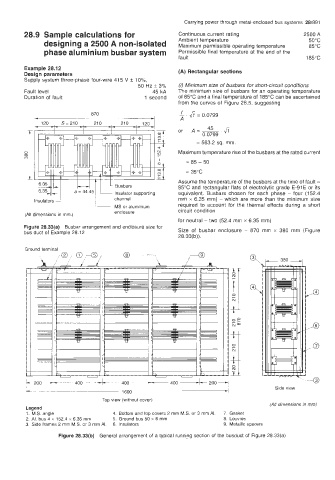

(All dimensions in mm )

for neutral -two (52.4 mm x 6.35 mm)

Figure 28.33(a) Busbar arrangement and enclosure size for

bus duct of ExamDle 28 12 Size of busbar enclosure - 870 mm x 380 mm (Figure

28.33(b))

Ground terminal

Side view

Top view (without cover)

(All dimensions in mm)

Legend

1. M.S. anqle 4. Bottom and top covers 2 mm M.S. or 3 mm AI. 7. Gasket

2. AI. bus i 152.4 x 6.35 mm 5. Ground bus 50 x 6 mm 8. Louvres

x

3. Side frames 2 mm M.S. or 3 mm AI. 6. Insulators 9. Metallic spacers

Figure 28.33(b) General arrangement of a typical running section of the busduct of Figure 28.33(a)