Page 992 - Industrial Power Engineering and Applications Handbook

P. 992

An isolated phase bus system 31/937

I- Generator

Indoor I Outdoor

/ *-e

k

k

Power house wall

-

i *, \

Hot air -

-. . - Tap-off t t7

1- .-

1-

to U.A.T

outlet

Generator

Unit aux. transformer

transformer

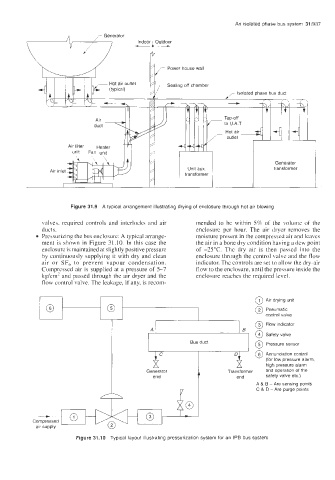

Figure 31.9 A typical arrangement illustrating drying of enclosure through hot air blowing

valves. required controls and interlocks and air mended to be within 5% of the volume of the

ducts. enclosure per hour. The air dryer removes the

Pressurizing the bus enclosure: A typical arrange- moisture present in the compressed air and leaves

ment is shown in Figure 31.10. In this case the the air in a bone dry condition having a dew point

enclosure is maintained at slightly positive pressure of -25°C. The dry air is then passed into the

by continuously supplying it with dry and clean enclosure through the control valve and the flow

air or SF, to prevent vapour condensation. indicator. The controls are set to allow the dry-air

Compressed air is supplied at a pressure of 5-7 flow to the enclosure, until the pressure inside the

kg/cm' and passed through the air dryer and the enclosure reaches the required level.

flow control valve. The leakage, if any, is recom-

2 Pneumatic

0 control valve

@ Safety valve

I Bus duct I 0 Pressure sensor

(for low pressure alarm,

high pressure alarm

Generator Transformer and operation of the

safety valve etc.)

A & B -Are sensing points

V I C 8. D - Are purge points

(3

- -

-

-

Compressed

air supply

Figure 31.10 Typical layout illustrating pressurization system for an IPB bus system