Page 989 - Industrial Power Engineering and Applications Handbook

P. 989

31/934 Industrial Power Engineering and Applications Handbook

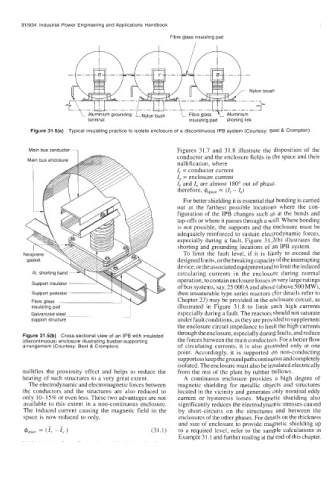

Fibre glass insulating pad

Figure 31.5(a) Typical insulating practice to isolate enclosure of a discontinuous IPB system (Courtesy: Best & Crompton)

Main bus conductor Figures 31.7 and 31.8 illustrate the disposition of the

conductor and the enclosure fields in the space and their

nullification, where

I, = conductor current

I, = enclosure current

I, and I, are almost 180" out of phase.

therefore, (I, - I,)

For better shielding it is essential that bonding is carried

out at the farthest possible locations where the con-

figuration of the IPB changes such as at the bends and

tap-offs or where it passes through a wall. Where bonding

is not possible, the supports and the enclosure must be

adequately reinforced to sustain electrodynamic forces,

especially during a fault. Figure 3 1.2(b) illustrates the

shorting and grounding locations of an IPB system.

To limit the fault level, if it is likely to exceed the

designed limits, or the breaking capacity of the interrupting

device, or the associatedequipment and to limit the induced

AI. shorting band circulating currents in the enclosure during normal

operation, to contain enclosure losses in very large ratings

Support insulator

of bus systems, say, 25 OOOA and above (above 500 MW),

then unsaturable type series reactors (for details refer to

Chapter 27) may be provided in the enclosure circuit, as

insulating pad illustrated in Figure 31.8 to limit such high currents

Galvanized steel especially during a fault. The reactors should not saturate

support structure under fault conditions, as they are provided to supplement

the enclosure circuit impedance to limit the high currents

through the enclosure, especially during faults, and reduce

Figure 31.5(b) Cross-sectional view of an IPB with insulated the forces between the main conductors. For a better flow

(discontinuous) enclosure illustrating busbar-supporting

arrangement (Courtesy: Best & Crompton) of circulating currents, it is also grounded only at one

point. Accordingly, it is supported on non-conducting

supports to keep the ground path continuous and completely

isolated. The enclosure must also be insulated electrically

nullifies the proximity effect and helps to reduce the from the rest of the plant by rubber bellows.

heating of such structures to a very great extent. A continuous enclosure provides a high degree of

The electrodynamic and electromagnetic forces between magnetic shielding for metallic objects and structures

the conductors and the structures are also reduced to located in the vicinity and generates only nominal eddy

only 10-15% or even less. These two advantages are not current or hysteresis losses. Magnetic shielding also

available to this extent in a non-continuous enclosure. significantly reduces the electrodynamic stresses caused

The induced current causing the magnetic field in the by short-circuits on the structures and between the

space is now reduced to only, enclosures of the other phases. For details on the thickness

and size of enclosure to provide magnetic shielding up

(31.1) to a required level, refer to the sample calculations in

Example 3 1.1 and further reading at the end of this chapter.