Page 206 - Instrumentation Reference Book 3E

P. 206

190 Fiber optics in sensor instrumentation

As an example, for a target surface moving in a a maximum modulation depth of 20 percent as

periodic sinusoidal motion such that: described (<1 MHz).

4TA .

Qs(t) = ~ sin(2rf,t) (12.33)

A0 12.4.4.2 Pseudo-heterodyne modiilation-vibra-

the resulting dynamic component of the output tiorz monitoring

signal is given by: A different form of optical fiber vibration moni-

tor has been described (Meggitt etal. 1989) for

use as a non-contacting reference grade vibration

sensor. It was initially designed for use in cali-

brating secondary grade accelerometers, such as

[sin (2& + QO>l piezoelectric accelerometers, but has a general

applicability. The advantage in using an optical

The output spectrum is composed of a carrier approach for a reference grade device is that the

centered at frequency fB with sidebands at fre- system is capable of making displacement meas-

quency differences of f~ +fs. fB zt Zfs, fB 4 3f, urements which are referred only to the wave-

and so on. It is possible to select the first term length of the radiation used, in this case a HeNe

fB +fs by use of a band pass filter centered atfB gas laser at 623.8 nm. It can also be configured to

and with a bandwidth of less than +2fs(max). provide calibrations that are independent of the

The output frequency modulated signal can be temperature of the environment, allowing the

conveniently demodulated by use of a PLL temperature dependence of the piezoelectric

where the output error signal is proportional devices to be characterized.

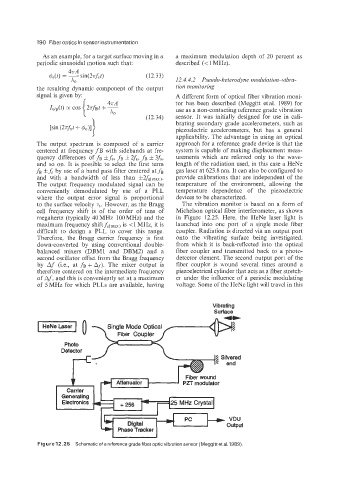

to the surface velocity v,. However, as the Bragg The vibration monitor is based on a form of

cell frequency shift is of the order of tens of Michelson optical fiber interferometer, as shown

megahertz (typically 40 MHz-100 MHz) and the in Figure 12.25. Here, the HeNe laser light is

maximum frequency shift&(,,,, is <1 MHz, it is launched into one port of a single mode fiber

difficult to design a PLL to cover this range. coupler. Radiation is directed via an output port

Therefore, the Bragg carrier frequency is first onto the vibrating surface being investigated,

down-converted by using conventional double- from which it is back-reflected into the optical

balanced mixers (DBM1 and DBM2) and a fiber coupler and transmitted back to a photo-

second oscillator offset from the Bragg frequency detector element. The second output port of the

by Af (i.e., at f~ + AJ). The mixer output is fiber coupler is wound several times around a

therefore centered on the intermediate frequency piezoelectrical cylinder that acts as a fiber stretch-

of Af, and this is conveniently set at a maximum er under the influence of a periodic modulating

of 5 MHz for which PLLs are available, having voltage. Some of the HeNe light will travel in this

Vibrating

Surface

I HeNeLaser I

Fiber Coupler

Photo

P2T modulator

VDU

output

Phase Tracker

Figure 12.25 Schematic of a referencegrade fiber opticvibration sensor (Meggitt et at. 1989).