Page 223 - System on Package_ Miniaturization of the Entire System

P. 223

Mixed-Signal (SOP) Design 197

C_resn1 C_resn2

L_cp

Cc Cc

Lm

Lm

Lc Lc

L1 L2

Cp1 Cp1

Rc Rc

CC

Lr Cr Cr Lr

C Ls 2

Rs

R12 R12

Cp1 Cp2

C_m1

L1 L2

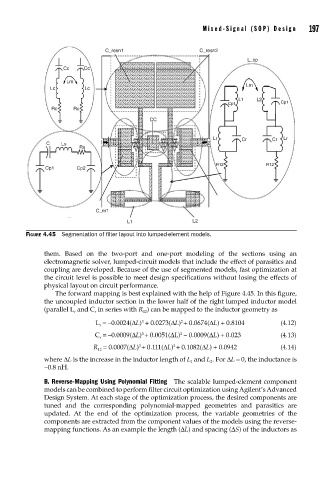

FIGURE 4.45 Segmentation of fi lter layout into lumped-element models.

them. Based on the two-port and one-port modeling of the sections using an

electromagnetic solver, lumped-circuit models that include the effect of parasitics and

coupling are developed. Because of the use of segmented models, fast optimization at

the circuit level is possible to meet design specifications without losing the effects of

physical layout on circuit performance.

The forward mapping is best explained with the help of Figure 4.45. In this figure,

the uncoupled inductor section in the lower half of the right lumped inductor model

(parallel L and C in series with R ) can be mapped to the inductor geometry as

r

r

12

2

3

L = –0.0024(ΔL) + 0.0273(ΔL) + 0.0674(ΔL) + 0.8104 (4.12)

r

3

2

C = –0.0009(ΔL) + 0.0051(ΔL) – 0.0009(ΔL) + 0.023 (4.13)

r

2

3

R = 0.0007(ΔL) + 0.111(ΔL) + 0.1082(ΔL) + 0.0942 (4.14)

12

where ΔL is the increase in the inductor length of L and L . For ΔL = 0, the inductance is

2

1

∼0.8 nH.

B. Reverse-Mapping Using Polynomial Fitting The scalable lumped-element component

models can be combined to perform filter circuit optimization using Agilent’s Advanced

Design System. At each stage of the optimization process, the desired components are

tuned and the corresponding polynomial-mapped geometries and parasitics are

updated. At the end of the optimization process, the variable geometries of the

components are extracted from the component values of the models using the reverse-

mapping functions. As an example the length (ΔL) and spacing (ΔS) of the inductors as