Page 100 - Sami Franssila Introduction to Microfabrication

P. 100

Thin-film Growth and Structure 79

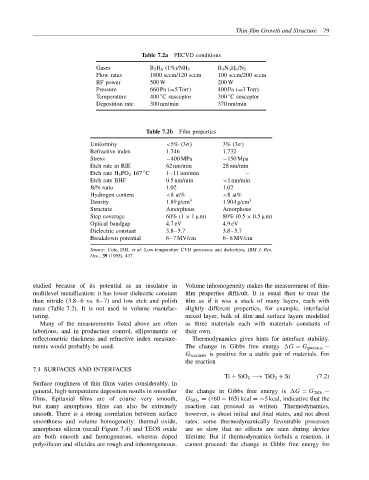

Table 7.2a PECVD conditions

Gases B 2 H 6 (1%)/NH 3 B 3 N 3 H 6 /N 2

Flow rates 1800 sccm/120 sccm 100 sccm/200 sccm

RF power 500 W 200 W

Pressure 660 Pa (=5 Torr) 400 Pa (=3 Torr)

◦

◦

Temperature 400 C susceptor 300 C susceptor

Deposition rate 300 nm/min 370 nm/min

Table 7.2b Film properties

Uniformity <5% (3σ) 3% (3σ)

Refractive index 1.746 1.732

Stress −400 MPa −150 Mpa

Etch rate in RIE 62 nm/min 28 nm/min

◦

Etch rate H 3 PO 4 167 C 1–11 nm/min –

Etch rate BHF 0.5 nm/min <1 nm/min

B/N ratio 1.02 1.02

Hydrogen content <8 at% <8 at%

Density 1.89 g/cm 3 1.904 g/cm 3

Structure Amorphous Amorphous

Step coverage 60% (1 × 1 µm) 80% (0.5 × 0.5 µm)

Optical bandgap 4.7 eV 4.9 eV

Dielectric constant 3.8–5.7 3.8–5.7

Breakdown potential 6–7 MV/cm 6–8 MV/cm

Source: Cote, D.R. et al: Low-temperature CVD processes and dielectrics, IBM J. Res.

Dev., 39 (1995), 437

studied because of its potential as an insulator in Volume inhomogeneity makes the measurement of thin-

multilevel metallization: it has lower dielectric constant film properties difficult. It is usual then to treat the

than nitride (3.8–6 vs. 6–7) and low etch and polish film as if it was a stack of many layers, each with

rates (Table 7.2). It is not used in volume manufac- slightly different properties, for example, interfacial

turing. mixed layer, bulk of film and surface layers modelled

Many of the measurements listed above are often as three materials each with materials constants of

laborious, and in production control, ellipsometric or their own.

reflectometric thickness and refractive index measure- Thermodynamics gives hints for interface stability.

ments would probably be used. The change in Gibbs free energy G = G products −

G reactants is positive for a stable pair of materials. For

the reaction

7.4 SURFACES AND INTERFACES

Ti + SiO 2 −→ TiO 2 + Si (7.2)

Surface roughness of thin films varies considerably. In

general, high-temperature deposition results in smoother the change in Gibbs free energy is G = G TiO 2 −

films. Epitaxial films are of course very smooth, G SiO 2 = (160 − 165) kcal = −5 kcal, indicative that the

but many amorphous films can also be extremely reaction can proceed as written. Thermodynamics,

smooth. There is a strong correlation between surface however, is about initial and final states, and not about

smoothness and volume homogeneity: thermal oxide, rates: some thermodynamically favourable processes

amorphous silicon (recall Figure 7.4) and TEOS oxide are so slow that no effects are seen during device

are both smooth and homogeneous, whereas doped lifetime. But if thermodynamics forbids a reaction, it

polysilicon and silicides are rough and inhomogeneous. cannot proceed: the change in Gibbs free energy for