Page 243 - Sami Franssila Introduction to Microfabrication

P. 243

222 Introduction to Microfabrication

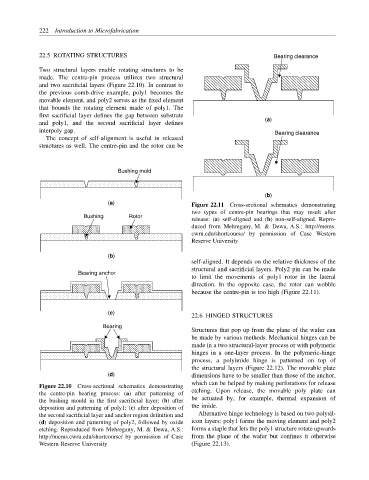

22.5 ROTATING STRUCTURES Bearing clearance

Two structural layers enable rotating structures to be

made. The centre-pin process utilizes two structural

and two sacrificial layers (Figure 22.10). In contrast to

the previous comb-drive example, poly1 becomes the

movable element, and poly2 serves as the fixed element

that bounds the rotating element made of poly1. The

first sacrificial layer defines the gap between substrate

(a)

and poly1, and the second sacrificial layer defines

interpoly gap. Bearing clearance

The concept of self-alignment is useful in released

structures as well. The centre-pin and the rotor can be

Bushing mold

(b)

(a) Figure 22.11 Cross-sectional schematics demonstrating

two types of centre-pin bearings that may result after

Bushing Rotor

release: (a) self-aligned and (b) non-self-aligned. Repro-

duced from Mehregany, M. & Dewa, A.S.: http://mems.

cwru.edu/shortcourse/ by permission of Case Western

Reserve University

(b)

self-aligned. It depends on the relative thickness of the

structural and sacrificial layers. Poly2 pin can be made

Bearing anchor

to limit the movements of poly1 rotor in the lateral

direction. In the opposite case, the rotor can wobble

because the centre-pin is too high (Figure 22.11).

(c)

22.6 HINGED STRUCTURES

Bearing

Structures that pop up from the plane of the wafer can

be made by various methods. Mechanical hinges can be

made in a two structural-layer process or with polymeric

hinges in a one-layer process. In the polymeric-hinge

process, a polyimide hinge is patterned on top of

the structural layers (Figure 22.12). The movable plate

(d) dimensions have to be smaller than those of the anchor,

which can be helped by making perforations for release

Figure 22.10 Cross-sectional schematics demonstrating

the centre-pin bearing process: (a) after patterning of etching. Upon release, the movable poly plate can

be actuated by, for example, thermal expansion of

the bushing mould in the first sacrificial layer; (b) after

deposition and patterning of poly1; (c) after deposition of the imide.

the second sacrificial layer and anchor region definition and Alternative hinge technology is based on two polysil-

(d) deposition and patterning of poly2, followed by oxide icon layers: poly1 forms the moving element and poly2

etching. Reproduced from Mehregany, M. & Dewa, A.S.: forms a staple that lets the poly1 structure rotate upwards

http://mems.cwru.edu/shortcourse/ by permission of Case from the plane of the wafer but confines it otherwise

Western Reserve University (Figure 22.13).