Page 244 - Sami Franssila Introduction to Microfabrication

P. 244

Sacrificial and Released Structures 223

Poly Si Polyimide

Polyimide

Aluminum Polysilicon

PSG

Si wafer Glass substrate

(a) (b)

Figure 22.12 (a) A polyimide hinge joins static and moving polysilicon plates and (b) polyimide hinged, electrostatically

actuated mirror. Reproduced from Suzuki, K. et al. (1994), by permission of IEEE

The material of the structural layer can be, for

instance silicon nitride, but epitaxial silicon can also be

used. Porous silicon is single-crystalline silicon and it is

possible to grow epitaxial film on it.

Porous silicon is a mechanically weak material, and

it can be destroyed by the capillary forces during drying

(a) (b) (cf. stiction where capillary forces pull free-standing

structures together upon drying). Porous silicon can be

Figure 22.13 Two-poly staple hinge: (a) side view and

(b) top view. Adapted from Pister, K. et al. (1992), by destroyed by gas bubbles as well: KOH etching releases

permission of Elsevier hydrogen (Equation 11.1), and if gas evolution is rapid,

the bubbles can burst porous structures. For this reason

dilute KOH, 0.1 to 1%, is used rather than 20 to 50%,

22.7 SACRIFICIAL STRUCTURES USING which is typical of silicon anisotropic etching.

POROUS SILICON In a modification of the above scheme, a free-standing

structure can be made of bulk single-crystal silicon. The

The electrochemical etch rate of n-type silicon (10–20 n-type silicon is intact in electrochemical etching and

ohm-cm) in an HF electrolyte is very low compared the p-type silicon underneath is fully transformed into

to p-type silicon or low-resistivity n-type silicon (ca. porous silicon (Figure 22.15).

0.01 ohm-cm) (Figure 22.14). Doping (by diffusion or

epitaxy) can, therefore, be used to create porous silicon

patterns. Alternatively, protective etch masks can be 22.8 EXERCISES

used, as in any other etching process. Photoresist,

silicon nitride, amorphous silicon and silicon carbide are 1. What etch selectivity is needed to release a 1 µm

candidates; silicon dioxide cannot be used because of the thick silicon nitride plate of 50 µm width by

HF electrolyte, and photoresists are limited to cases with sacrificial-oxide etching (49% HF, rate 2 µm/min)

diluted HF. if plate thickness variation due to etching has to

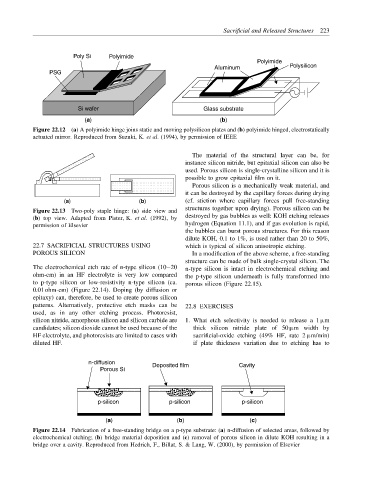

n-diffusion Deposited film Cavity

Porous Si

p-silicon p-silicon p-silicon

(a) (b) (c)

Figure 22.14 Fabrication of a free-standing bridge on a p-type substrate: (a) n-diffusion of selected areas, followed by

electrochemical etching; (b) bridge material deposition and (c) removal of porous silicon in dilute KOH resulting in a

bridge over a cavity. Reproduced from Hedrich, F., Billat, S. & Lang, W. (2000), by permission of Elsevier