Page 311 - Sami Franssila Introduction to Microfabrication

P. 311

290 Introduction to Microfabrication

Wafer Mask

Chuck

BSA splitfield Focusing and storage of

microscope mask alignment marks

Mask

alignment

mark

Wafer

alignment

mark

Focusing of substrate alignment marks

Alignment

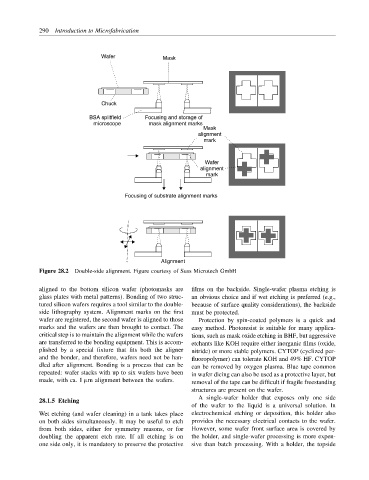

Figure 28.2 Double-side alignment. Figure courtesy of Suss Microtech GmbH

aligned to the bottom silicon wafer (photomasks are films on the backside. Single-wafer plasma etching is

glass plates with metal patterns). Bonding of two struc- an obvious choice and if wet etching is preferred (e.g.,

tured silicon wafers requires a tool similar to the double- because of surface quality considerations), the backside

side lithography system. Alignment marks on the first must be protected.

wafer are registered, the second wafer is aligned to those Protection by spin-coated polymers is a quick and

marks and the wafers are then brought to contact. The easy method. Photoresist is suitable for many applica-

critical step is to maintain the alignment while the wafers tions, such as mask oxide etching in BHF, but aggressive

are transferred to the bonding equipment. This is accom- etchants like KOH require either inorganic films (oxide,

plished by a special fixture that fits both the aligner nitride) or more stable polymers. CYTOP (cyclized per-

and the bonder, and therefore, wafers need not be han- fluoropolymer) can tolerate KOH and 49% HF. CYTOP

dled after alignment. Bonding is a process that can be can be removed by oxygen plasma. Blue tape common

repeated: wafer stacks with up to six wafers have been in wafer dicing can also be used as a protective layer, but

made, with ca. 1 µm alignment between the wafers. removal of the tape can be difficult if fragile freestanding

structures are present on the wafer.

A single-wafer holder that exposes only one side

28.1.5 Etching

of the wafer to the liquid is a universal solution. In

Wet etching (and wafer cleaning) in a tank takes place electrochemical etching or deposition, this holder also

on both sides simultaneously. It may be useful to etch provides the necessary electrical contacts to the wafer.

from both sides, either for symmetry reasons, or for However, some wafer front surface area is covered by

doubling the apparent etch rate. If all etching is on the holder, and single-wafer processing is more expen-

one side only, it is mandatory to preserve the protective sive than batch processing. With a holder, the topside