Page 83 - Sami Franssila Introduction to Microfabrication

P. 83

62 Introduction to Microfabrication

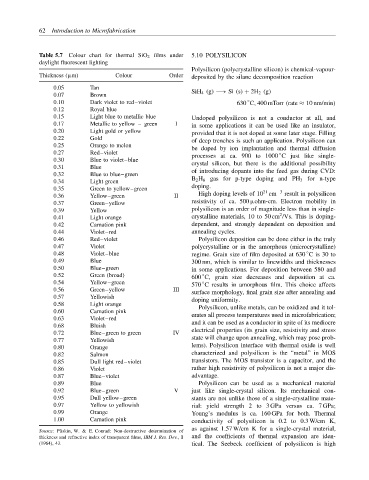

Table 5.7 Colour chart for thermal SiO 2 films under 5.10 POLYSILICON

daylight fluorescent lighting

Polysilicon (polycrystalline silicon) is chemical-vapour-

Thickness (µm) Colour Order deposited by the silane decomposition reaction

0.05 Tan

0.07 Brown SiH 4 (g) −→ Si (s) + 2H 2 (g)

◦

0.10 Dark violet to red–violet 630 C, 400 mTorr (rate ≈ 10 nm/min)

0.12 Royal blue

0.15 Light blue to metallic blue Undoped polysilicon is not a conductor at all, and

0.17 Metallic to yellow – green I in some applications it can be used like an insulator,

0.20 Light gold or yellow provided that it is not doped at some later stage. Filling

0.22 Gold of deep trenches is such an application. Polysilicon can

0.25 Orange to melon be doped by ion implantation and thermal diffusion

0.27 Red–violet processes at ca. 900 to 1000 C just like single-

◦

0.30 Blue to violet–blue crystal silicon, but there is the additional possibility

0.31 Blue

0.32 Blue to blue–green of introducing dopants into the feed gas during CVD:

0.34 Light green B 2 H 6 gas for p-type doping and PH 3 for n-type

0.35 Green to yellow–green doping.

21

High doping levels of 10 cm −3 result in polysilicon

0.36 Yellow–green II

0.37 Green–yellow resistivity of ca. 500 µohm-cm. Electron mobility in

0.39 Yellow polysilicon is an order of magnitude less than in single-

2

0.41 Light orange crystalline materials, 10 to 50 cm /Vs. This is doping-

0.42 Carnation pink dependent, and strongly dependent on deposition and

0.44 Violet–red annealing cycles.

0.46 Red–violet Polysilicon deposition can be done either in the truly

0.47 Violet polycrystalline or in the amorphous (microcrystalline)

◦

0.48 Violet–blue regime. Grain size of film deposited at 630 C is 30 to

0.49 Blue 300 nm, which is similar to linewidths and thicknesses

0.50 Blue–green in some applications. For deposition between 580 and

0.52 Green (broad) 600 C, grain size decreases and deposition at ca.

◦

0.54 Yellow–green ◦

570 C results in amorphous film. This choice affects

0.56 Green–yellow III surface morphology, final grain size after annealing and

0.57 Yellowish doping uniformity.

0.58 Light orange Polysilicon, unlike metals, can be oxidized and it tol-

0.60 Carnation pink

0.63 Violet–red erates all process temperatures used in microfabrication;

0.68 Bluish and it can be used as a conductor in spite of its mediocre

0.72 Blue–green to green IV electrical properties (its grain size, resistivity and stress

0.77 Yellowish state will change upon annealing, which may pose prob-

0.80 Orange lems). Polysilicon interface with thermal oxide is well

0.82 Salmon characterized and polysilicon is the “metal” in MOS

0.85 Dull light red–violet transistors. The MOS transistor is a capacitor, and the

0.86 Violet rather high resistivity of polysilicon is not a major dis-

0.87 Blue–violet advantage.

0.89 Blue Polysilicon can be used as a mechanical material

0.92 Blue–green V just like single-crystal silicon. Its mechanical con-

0.95 Dull yellow–green stants are not unlike those of a single-crystalline mate-

0.97 Yellow to yellowish rial: yield strength 2 to 3 GPa versus ca. 7 GPa;

0.99 Orange Young’s modulus is ca. 160 GPa for both. Thermal

1.00 Carnation pink conductivity of polysilicon is 0.2 to 0.3 W/cm K,

as against 1.57 W/cm K for a single-crystal material,

Source: Pliskin, W. & E. Conrad: Non-destructive determination of

thickness and refractive index of transparent films, IBM J. Res. Dev., 1 and the coefficients of thermal expansion are iden-

(1964), 43. tical. The Seebeck coefficient of polysilicon is high