Page 130 - Low Temperature Energy Systems with Applications of Renewable Energy

P. 130

Effective use of heat pumps for various heating applications 119

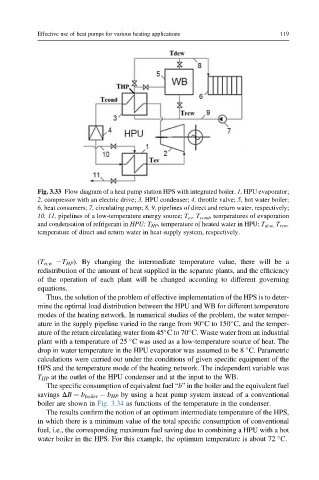

Fig. 3.33 Flow diagram of a heat pump station HPS with integrated boiler. 1, HPU evaporator;

2, compressor with an electric drive; 3, HPU condenser; 4, throttle valve; 5, hot water boiler;

6, heat consumers; 7, circulating pump; 8, 9, pipelines of direct and return water, respectively;

10, 11, pipelines of a low-temperature energy source; T ev ,T cond , temperatures of evaporation

and condensation of refrigerant in HPU; T HP , temperature of heated water in HPU; T dcw, T rcw ,

temperature of direct and return water in heat supply system, respectively.

(T rcw eT HP ). By changing the intermediate temperature value, there will be a

redistribution of the amount of heat supplied in the separate plants, and the efficiency

of the operation of each plant will be changed according to different governing

equations.

Thus, the solution of the problem of effective implementation of the HPS is to deter-

mine the optimal load distribution between the HPU and WB for different temperature

modes of the heating network. In numerical studies of the problem, the water temper-

ature in the supply pipeline varied in the range from 90 S to 150 S, and the temper-

ature of the return circulating water from 45 S to 70 S. Waste water from an industrial

plant with a temperature of 25 C was used as a low-temperature source of heat. The

drop in water temperature in the HPU evaporator was assumed to be 8 C. Parametric

calculations were carried out under the conditions of given specific equipment of the

HPS and the temperature mode of the heating network. The independent variable was

T HP at the outlet of the HPU condenser and at the input to the WB.

The specific consumption of equivalent fuel “b” in the boiler and the equivalent fuel

savings DB ¼ b boiler b HP by using a heat pump system instead of a conventional

boiler are shown in Fig. 3.34 as functions of the temperature in the condenser.

The results confirm the notion of an optimum intermediate temperature of the HPS,

in which there is a minimum value of the total specific consumption of conventional

fuel, i.e., the corresponding maximum fuel saving due to combining a HPU with a hot

water boiler in the HPS. For this example, the optimum temperature is about 72 C.