Page 117 - MEMS and Microstructures in Aerospace Applications

P. 117

Osiander / MEMS and microstructures in Aerospace applications DK3181_c005 Final Proof page 105 25.8.2005 3:39pm

Space Radiation Effects and Microelectromechanical Systems 105

100

Normal operation

80 Device spec

Actuation voltages (V) 40 0 Reverse polarity 67 hr Unbiased

60

anneal

Bias at +90V

24 hr

20

Dose rate 50 R/s

at 25 C at

125 C

−20

−40 (Diagnostic measurement)

−60

0 50 100 150 200 250 300

Dose [krd(GaAs)]

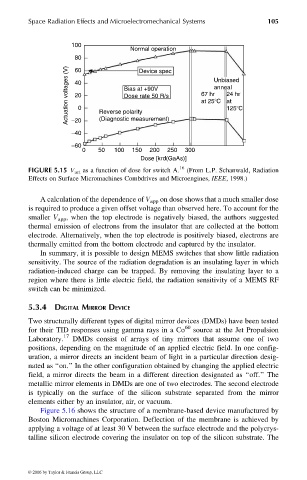

FIGURE 5.15 V act as a function of dose for switch A. 16 (From L.P. Schanwald, Radiation

Effects on Surface Micromachines Combdrives and Microengines, IEEE, 1998.)

A calculation of the dependence of V app on dose shows that a much smaller dose

is required to produce a given offset voltage than observed here. To account for the

smaller V app , when the top electrode is negatively biased, the authors suggested

thermal emission of electrons from the insulator that are collected at the bottom

electrode. Alternatively, when the top electrode is positively biased, electrons are

thermally emitted from the bottom electrode and captured by the insulator.

In summary, it is possible to design MEMS switches that show little radiation

sensitivity. The source of the radiation degradation is an insulating layer in which

radiation-induced charge can be trapped. By removing the insulating layer to a

region where there is little electric field, the radiation sensitivity of a MEMS RF

switch can be minimized.

5.3.4 DIGITAL MIRROR DEVICE

Two structurally different types of digital mirror devices (DMDs) have been tested

for their TID responses using gamma rays in a Co 60 source at the Jet Propulsion

Laboratory. 17 DMDs consist of arrays of tiny mirrors that assume one of two

positions, depending on the magnitude of an applied electric field. In one config-

uration, a mirror directs an incident beam of light in a particular direction desig-

nated as ‘‘on.’’ In the other configuration obtained by changing the applied electric

field, a mirror directs the beam in a different direction designated as ‘‘off.’’ The

metallic mirror elements in DMDs are one of two electrodes. The second electrode

is typically on the surface of the silicon substrate separated from the mirror

elements either by an insulator, air, or vacuum.

Figure 5.16 shows the structure of a membrane-based device manufactured by

Boston Micromachines Corporation. Deflection of the membrane is achieved by

applying a voltage of at least 30 V between the surface electrode and the polycrys-

talline silicon electrode covering the insulator on top of the silicon substrate. The

© 2006 by Taylor & Francis Group, LLC