Page 113 - MEMS and Microstructures in Aerospace Applications

P. 113

Osiander / MEMS and microstructures in Aerospace applications DK3181_c005 Final Proof page 101 25.8.2005 3:39pm

Space Radiation Effects and Microelectromechanical Systems 101

electric fields between the fingers. That could cause one set of fingers to move

relative to the other. The result is a change in the capacitance between the two sets

of interdigitated fingers that results in a change in the output voltage.

The proposed mechanism of charge generation and trapping in the insulators

causing a shift in V out was confirmed by testing another accelerometer (ADXL04)

that contained a conducting polycrystalline silicon layer on top of the insulators.

That layer was electrically connected to the moveable set of fingers. The conducting

layer effectively screens out any charge generated in the insulators, so that the

mechanical part of the device should exhibit no radiation-induced changes. Irradi-

ation of the device with protons confirmed that there was no change in V out .

Mathematical modeling also confirmed that charge trapping in the insulators

could cause an offset in V out . 14 Another investigation showed that very high doses

of radiation actually caused the device to lock up and stop operating, presumably by

bending the beams to such an extent that they made contact with the substrate. 15

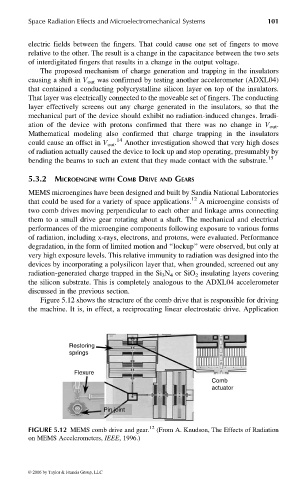

5.3.2 MICROENGINE WITH COMB DRIVE AND GEARS

MEMS microengines have been designed and built by Sandia National Laboratories

that could be used for a variety of space applications. 12 A microengine consists of

two comb drives moving perpendicular to each other and linkage arms connecting

them to a small drive gear rotating about a shaft. The mechanical and electrical

performances of the microengine components following exposure to various forms

of radiation, including x-rays, electrons, and protons, were evaluated. Performance

degradation, in the form of limited motion and ‘‘lockup’’ were observed, but only at

very high exposure levels. This relative immunity to radiation was designed into the

devices by incorporating a polysilicon layer that, when grounded, screened out any

radiation-generated charge trapped in the Si 3 N 4 or SiO 2 insulating layers covering

the silicon substrate. This is completely analogous to the ADXL04 accelerometer

discussed in the previous section.

Figure 5.12 shows the structure of the comb drive that is responsible for driving

the machine. It is, in effect, a reciprocating linear electrostatic drive. Application

Restoring

springs

Flexure

Comb

actuator

Pin joint

FIGURE 5.12 MEMS comb drive and gear. 12 (From A. Knudson, The Effects of Radiation

on MEMS Accelerometers, IEEE, 1996.)

© 2006 by Taylor & Francis Group, LLC