Page 114 - MEMS and Microstructures in Aerospace Applications

P. 114

Osiander / MEMS and microstructures in Aerospace applications DK3181_c005 Final Proof page 102 25.8.2005 3:39pm

102 MEMS and Microstructures in Aerospace Applications

and removal of bias between the two sets of interdigitated teeth cause them to move

back and forth in a direction parallel to the long dimension of the teeth. Two sets of

comb drives located such that their linear movements are perpendicular to each

other are used to drive a cog connected to an axle. During movement, the comb is

subjected to both adhesive and abrasive wear, as well as to microwelding and

electrostatic clamping. These failure modes are the result of the very small spacing

between the two sets of interdigitated fingers and between the comb fingers and the

substrate. Trapped charge could cause the two sets of fingers to make contact with

one another or to make contact with the substrate. The much larger tooth-to-

substrate capacitance suggests that the buildup of charge will be much more

effective in bending the teeth towards the substrate. Because it is important to

prevent this from happening, a grounded polysilicon layer was deposited on the

substrate below the comb teeth, and any radiation-induced charge trapped in the

Si 3 N 4 or SiO 2 layer below the polysilicon layer could be screened from the comb

teeth. Permitting the comb fingers to bend down and make contact with the

substrate would lead to the enhanced likelihood of abrasion, microwelding, and

electrostatic clamping.

The magnitude of the charge trapped in the oxide was obtained by measuring

the capacitance between the comb and the substrate following each radiation

exposure. Radiation-induced wear in the comb was obtained by measuring the

resonant operating frequency spectrum of the micromotor: the maximum of

the resonant frequency spectrum decreases with wear. Radiation effects in the

gear drive were quantified by measuring the reduction in the rotation rate of

the gear with radiation dose. During irradiation, three different bias configurations

were used — all pins floating, all pins grounded, or all pins biased in a particular

configuration.

Experimental results indicated that the configuration in which all the pins were

grounded is the one in which the microengine was the least sensitive to radiation-

induced changes. For instance, the gear rotation rate decreased only slightly, while

the resonant frequency response for the grounded comb drive did not change for

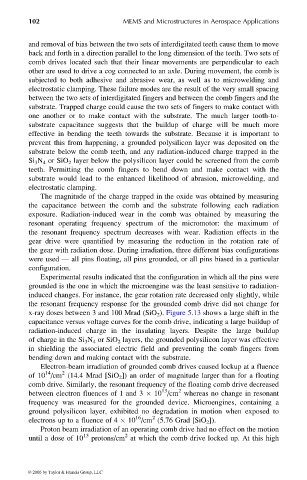

x-ray doses between 3 and 100 Mrad (SiO 2 ). Figure 5.13 shows a large shift in the

capacitance versus voltage curves for the comb drive, indicating a large buildup of

radiation-induced charge in the insulating layers. Despite the large buildup

of charge in the Si 3 N 4 or SiO 2 layers, the grounded polysilicon layer was effective

in shielding the associated electric field and preventing the comb fingers from

bending down and making contact with the substrate.

Electron-beam irradiation of grounded comb drives caused lockup at a fluence

14

2

of 10 /cm (14.4 Mrad [SiO 2 ]) an order of magnitude larger than for a floating

comb drive. Similarly, the resonant frequency of the floating comb drive decreased

2

13

between electron fluences of 1 and 3 10 /cm whereas no change in resonant

frequency was measured for the grounded device. Microengines, containing a

ground polysilicon layer, exhibited no degradation in motion when exposed to

2

16

electrons up to a fluence of 4 10 /cm (5.76 Grad [SiO 2 ]).

Proton beam irradiation of an operating comb drive had no effect on the motion

2

until a dose of 10 13 protons/cm at which the comb drive locked up. At this high

© 2006 by Taylor & Francis Group, LLC