Page 427 -

P. 427

7-16 MEMS: Design and Fabrication

pads that extend over the oxide. Therefore, the spreading and contact resistance, R and R , respectively,

s c

can be calculated by

V V

BC

AB

R R (7.14)

c

s

I

AD

The resistance of the probes in these measurements was negligible. Since the main parameter of interest in

these measurements was the overall change in resistance under the contact, R and R were lumped together

c s

in determining the contact resistivity.As a result of the lumping together of the spreading and contact resist-

ances, the result was considered to be on the high end of the average specific contact resistivity.

7.4.2 Characterization of Ti/TiN/Pt Metallization

Several (0001)-oriented, highly resistive, Si-face, p-type 6H-SiC substrates, each with n-type epilayers

19

17

3

(1µm thick) of different doping levels ranging between 3.3 10 cm 3 and 1.9 10 m , were pur-

chased from Cree Research, Inc. The wafers were initially cleaned by modified RCA method and dipped

in 49% HF for five seconds, followed by rinsing and blow-drying.An ex situ dehydration process, at 200°C

in nitrogen ambient for 20 minutes to desorb water trapped within the micropipes, followed this cleaning

process. Depositions of Ti (50nm)/TiN (50nm)/Pt (100nm) were made on the samples by sputtering

without breaking vacuum.Titanium nitride was obtained by reactive sputtering of titanium in 20% nitrogen/

argon ambient. The top platinum layer was etched in light aqua regia to form rectangular and circular

probe pads that overlapped the field oxide. The exposed TiN/Ti on the field oxide was selectively etched

in 1:1 EDTA:H O to electrically isolate. The pads offered total coverage of the contact regions and facil-

2

2

itated broad area probe contact during testing. In the as-deposited state, the titanium contact on the n-

3

19

type epilayer was ohmic for the sample with the highest doping level (1.9 10 cm ). The contact

5

resistance using Equation (7.13) was found to be approximately 1 10 cm . In order to obtain ohmic

18

17

3

contact to n-type 6H-SiC with lower doping levels (3.3 10 –10 cm ), high-temperature annealing

was required.

The experimental results of the Ti/TiN/Pt ohmic contact are summarized in Table 7.2. The I–V char-

acteristics of the as-deposited metallization on all samples were rectifying, except for the highest doped

19

3

sample (1.9 10 cm ). After 30 to 60 seconds of rapid thermal anneal at 1000°C in argon ambient,

ohmic contact was achieved on all samples except for the lightest doped, which remained rectifying after

three and a half minutes of annealing. The average barrier height before annealing was obtained from the

forward I–V characteristic curve using the thermionic emission model:

qV

s 1

J J e nkT (7.15a)

2

where J is the forward current density (A/cm ); V is the applied voltage; q is the electronic charge; k is the

Boltzman constant; T is the temperature (K); and n is the ideality factor that models the deviation from

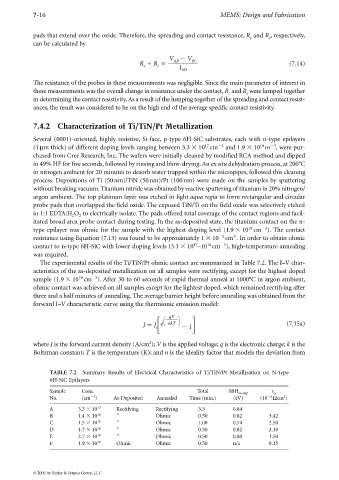

TABLE 7.2 Summary Results of Electrical Characteristics of Ti/TiN/Pt Metallization on N-type

6H-SiC Epilayers

Sample Conc. Total SBH as-dep r cs

3

2

4

No. (cm ) As-Deposited Annealed Time (min.) (eV) (10 Ωcm )

A 3.3 10 17 Rectifying Rectifying 3.5 0.84

B 1.4 10 18 ” Ohmic 0.50 0.82 3.42

C 1.5 10 18 ” Ohmic 1.00 0.74 2.50

D 1.7 10 18 ” Ohmic 0.50 0.82 2.10

E 2.7 10 18 ” Ohmic 0.50 0.80 1.50

F 1.9 10 19 Ohmic Ohmic 0.50 n/a 0.15

© 2006 by Taylor & Francis Group, LLC