Page 502 -

P. 502

Polymer Microsystems: Materials and Fabrication 9-23

(a)

Non-polymerizable UV (b) (c)

solution

Polymer

solution

Polymer

fiber

(d) (e)

Non-polymerizable UV (f)

solution

Polymer

microtube

Polymer

solution

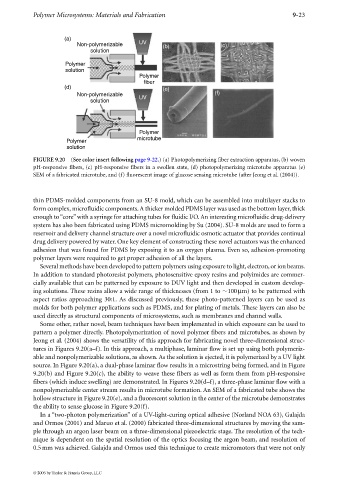

FIGURE 9.20 (See color insert following page 9-22.) (a) Photopolymerizing fiber extraction apparatus, (b) woven

pH-responsive fibers, (c) pH-responsive fibers in a swollen state, (d) photopolymerizing microtube apparatus (e)

SEM of a fabricated microtube, and (f) fluorescent image of glucose sensing microtube (after Jeong et al. (2004)).

thin PDMS-molded components from an SU-8 mold, which can be assembled into multilayer stacks to

form complex, microfluidic components.A thicker molded PDMS layer was used as the bottom layer, thick

enough to“core”with a syringe for attaching tubes for fluidic I/O. An interesting microfluidic drug-delivery

system has also been fabricated using PDMS micromolding by Su (2004). SU-8 molds are used to form a

reservoir and delivery channel structure over a novel microfluidic osmotic actuator that provides continual

drug delivery powered by water. One key element of constructing these novel actuators was the enhanced

adhesion that was found for PDMS by exposing it to an oxygen plasma. Even so, adhesion-promoting

polymer layers were required to get proper adhesion of all the layers.

Several methods have been developed to pattern polymers using exposure to light, electron, or ion beams.

In addition to standard photoresist polymers, photosensitive epoxy resins and polyimides are commer-

cially available that can be patterned by exposure to DUV light and then developed in custom develop-

ing solutions. These resins allow a wide range of thicknesses (from 1 to 100µm) to be patterned with

aspect ratios approaching 30:1. As discussed previously, these photo-patterned layers can be used as

molds for both polymer applications such as PDMS, and for plating of metals. These layers can also be

used directly as structural components of microsystems, such as membranes and channel walls.

Some other, rather novel, beam techniques have been implemented in which exposure can be used to

pattern a polymer directly. Photopolymerization of novel polymer fibers and microtubes, as shown by

Jeong et al. (2004) shows the versatility of this approach for fabricating novel three-dimensional struc-

tures in Figures 9.20(a–f). In this approach, amultiphase, laminar flow is set up using both polymeriz-

able and nonpolymerizable solutions, as shown. As the solution is ejected, it is polymerized by a UV light

source. In Figure 9.20(a), a dual-phase laminar flow results in a microstring being formed, and in Figure

9.20(b) and Figure 9.20(c), the abilitytoweave these fibers as well as form them from pH-responsive

fibers (which induce swelling) are demonstrated. In Figures 9.20(d–f), a three-phase laminar flow with a

nonpolymerizable center stream results in microtube formation. An SEM of a fabricated tube shows the

hollow structure in Figure 9.20(e), and a fluorescent solution in the center of the microtube demonstrates

the ability to sense glucose in Figure 9.20(f).

In a “two-photon polymerization” of a UV-light-curing optical adhesive (Norland NOA 63), Galajda

and Ormos (2001) and Maruo et al. (2000) fabricated three-dimensional structures by moving the sam-

ple through an argon laser beam on a three-dimensional piezoelectric stage. The resolution of the tech-

nique is dependent on the spatial resolution of the optics focusing the argon beam, and resolution of

0.5mm was achieved. Galajda and Ormos used this technique to create micromotors that were not only

© 2006 by Taylor & Francis Group, LLC