Page 689 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 689

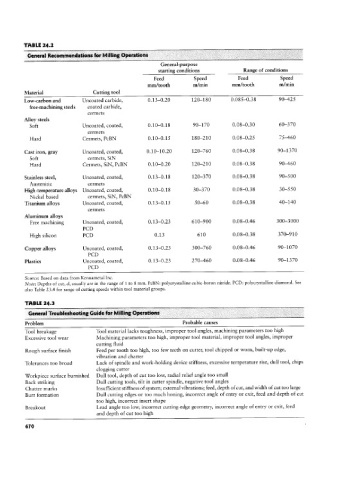

TABLE 24.2

General Recommendations fur Milling Operations

General-purpose

starting conditions Range of conditions

Feed Speed Feed Speed

mm/tooth m/min mm/tooth m/min

Material Cutting tool

Low-carbon and Uncoated carbide, 0.13-0.20 120-180 0.085-0.38 90-425

free-machining steels coated carbide,

cermets

Alloy steels

Soft Uncoated, coated, 0.10-0.18 90-170 0.08-0.30 60-370

cermets

Hard Cermets, PCBN 0.10-0.15 180-210 0.08-0.25 75-460

Cast iron, gray Uncoated, coated, 0.10-10.20 120-760 0.08-0.38 90-1370

Soft cermets, SiN

Hard Cerrnets, SiN, PCBN 0.10-0.20 120-210 0.08-0.38 90-460

Stainless steel, Uncoated, coated, 0.13-0.18 120-370 0.08-0.38 90-500

Austenitic cermets

High-temperature alloys Uncoated, coated, 0.10-0.1 8 30-370 0.08-0.38 30-550

Nickel based cermets, SiN, PCBN

Titanium alloys Uncoated, coated, 0.13-0.15 50-60 0.08-0.38 40-140

cermets

Aluminum alloys

Free machining Uncoated, coated, 0.13-0.23 610-900 0.08-0.46 300-3000

PCD

High silicon PCD 0.13 610 0.08-0.38 370-910

Copper alloys Uncoated, coated, 0.13-0.23 300-760 0.08-0.46 90-1070

PCD

Plastics Uncoated, coated, 0.13-0.23 270-460 0.08-0.46 90-1370

PCD

Source: Based on data from Kennametal Inc.

Note: Depths of cut, d, usually are in the range of 1 to 8 rnm. PcBN: polycrystalline cubic-boron nitride. PCD: polycrystalline diamond. See

also Table 23.4 for range of cutting speeds within tool material groups.

TABLE 24.3

General Troubleshooting Guide for Milling Qperations

Problem Probable causes

Tool breakage Tool material lacks toughness, improper tool angles, machining parameters too high

Excessive tool wear Machining parameters too high, improper tool material, improper tool angles, improper

cutting fluid

Rough surface finish Feed per tooth too high, too few teeth on cutter, tool chipped or worn, built-up edge,

vibration and chatter

Tolerances too broad Lack of spindle and work-holding device stiffness, excessive temperature rise, dull tool, chips

clogging cutter

Workpiece surface burnished Dull tool, depth of cut too low, radial relief angle too small

Back striking Dull cutting tools, tilt in cutter spindle, negative tool angles

Chatter marks Insufficient stiffness of system; external vibrations; feed, depth of cut, and width of cut too large

Burr formation Dull cutting edges or too much honing, incorrect angle of entry or exit, feed and depth of cut

too high, incorrect insert shape

Breakout Lead angle too low, incorrect cutting-edge geometry, incorrect angle of entry or exit, feed

and depth of cut too high

670