Page 691 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 691

2 Chapter 24 Machining Processes: Milling, Broaching, Sawing, Filing, and Gear Manufacturing

24.2.8 Milling Machines

Because they are capable of performing a variety of cutting operations, milling ma-

chines are among the most versatile and useful machine tools. The first milling ma-

chine was built in 182.0 by Eli Whitney (1765-1825). A wide selection of milling

machines with numerous features is now available. The features of typical standard

milling machines are described next. Note, however, that many of these machines

and operations are now being replaced with computer controls and machining cen-

ters. Inexpensive, manually controlled machines are still widely used, especially for

small production runs.

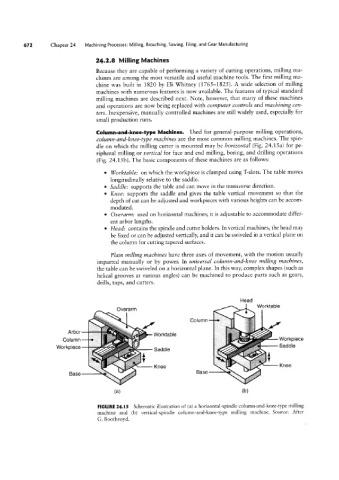

Column-and-knee-type Machines. Used for general-purpose milling operations,

column-and-knee-type machines are the most common milling machines. The spin-

dle on which the milling cutter is mounted may be horizontal (Fig. 24.l5a) for pe-

ripheral milling or vertical for face and end milling, boring, and drilling operations

(Fig. 24.15 b). The basic components of these machines are as follows:

° Worktable: on which the workpiece is clamped using T-slots. The table moves

longitudinally relative to the saddle.

° Saddle: supports the table and can move in the transverse direction.

° Knee: supports the saddle and gives the table vertical movement so that the

depth of cut can be adjusted and workpieces with various heights can be accom-

"`”‘

modated.

° O1/erarm: used on horizontal machines; it is adjustable to accommodate differ-

tl»e

ent arbor lengths.

W°"<P‘@°e

° Head: contains the spindle and cutter holders. In vertical machines, the head may

be fixed or can be adjusted vertically, and it can be swiveled in a vertical plane on

the column for cutting tapered surfaces.

Plain milling machines have three axes of movement, with the motion usually

imparted manually or by power. In universal column-and-knee milling machines,

the table can be swiveled on a horizontal plane. In this way, complex shapes (such as

helical grooves at various angles) can be machined to produce parts such as gears,

drills, taps, and cutters.

Overarm /

.. .

d

H

ea

Worktable

Arbor °% C°'Um“

Knee 5”

Base saddie BHSQ ~ Vppy Saddle

if>Lii1;f

C ».i~~ W°'k*ab'e | »

°'Umf1 1 li i Wolkplece

'Wi'

if

Knee

..

(H) ,»,,` (D)

FIGURE 24.l5 Schematic illustration of (al a horizontal-spindle column-and-knee-type milling

machine and (b) vertical-spindle column-and-knee-type milling machine. Source: After

G. Boothroyd.