Page 695 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 695

Chapter 24 Machining Processes: Milling, Broaching, Sawing, Filing, and Gear Manufacturing

hook angle _X Pi1Cl'1 /-_ an d Clearance angle

Fiake or

|_

,orer

/V

<-

Chip gullet

Back-off or

~' ,liii ""

Tooth

,_,_ depth T

__ f ;a,_,e <1

Workpiece Root radius

(H) (D)

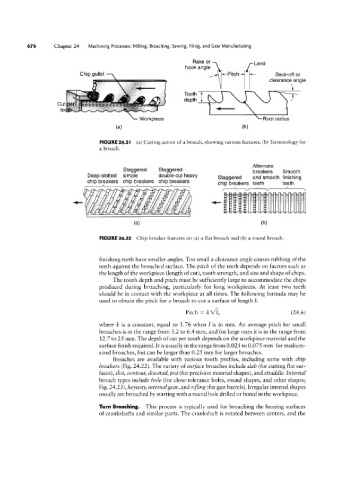

FIGURE 24.2l (a) Cutting action of a broach, showing various features. (b) Terminology for

a broach.

Alternate

eteggelee Sleggered breakers Smooth

Deep-slotted simple double-cut heavy staggered ehd Smooth hhiehihe

chip breakers chip breakers chip breakers Chip breakers teeth teeth

K E. rw,, 2 e l V ,ee _ 1- - N I _ _ W A \/ A \

la) (D)

FIGURE 24.22 Chip breaker features on (a) a flat broach and (b) a round broach.

finishing teeth have smaller angles. Too small a clearance angle causes rubbing of the

teeth against the broached surface. The pitch of the teeth depends on factors such as

the length of the workpiece (length of cut), tooth strength, and size and shape of chips.

The tooth depth and pitch must be sufficiently large to accommodate the chips

produced during broaching, particularly for long workpieces. At least two teeth

should be in contact with the workpiece at all times. The following formula may be

used to obtain the pitch for a broach to cut a surface of length l:

Pitch = /QW, (24.6)

where le is a constant, equal to 1.76 when l is in mm. An average pitch for small

broaches is in the range from 3.2 to 6.4 mm, and for large ones it is in the range from

12.7 to 25 mm. The depth of cut per tooth depends on the workpiece material and the

surface finish required. It is usually in the range from 0.025 to 0.075 mm for medium-

sized broaches, but can be larger than 0.25 mm for larger broaches.

Broaches are available with various tooth profiles, including some with chip

breakers (Fig. 24.22). The variety of surface broaches include slab (for cutting flat sur-

faces), slot, contour; dovetail, pot (for precision external shapes), and straddle. Internal

broach types include /role (for close-tolerance holes, round shapes, and other shapes;

Fig. 24.23), ke;/way, internal gear, and rifling (for gun barrels). Irregular internal shapes

usually are broached by starting with a round hole drilled or bored in the workpiece.

Turn Broaching. This process is typically used for broaching the bearing surfaces

of crankshafts and similar parts. The crankshaft is rotated between centers, and the