Page 697 - Manufacturing Engineering and Technology - Kalpakjian, Serope : Schmid, Steven R.

P. 697

678 Chapter 24 Machining Processes: Milling, Broaching, Sawing, Filing, and Gear Manufacturing

° The use of standardized parts is especially important for broaches. Keyvvays,

splines, gear teeth, etc., all have standard sizes, and these dimensions allow the

use of common broaches.

° Balanced cross sections are preferable to keep the broach from drifting, thus

maintaining close tolerances.

° Radii are difficult to produce in broaching, and chamfers are preferred.

° Inverted or dovetail splines should be avoided.

° Broaching blind holes should be avoided Whenever possible, but if necessary,

there must be a relief at the end of the broached area.

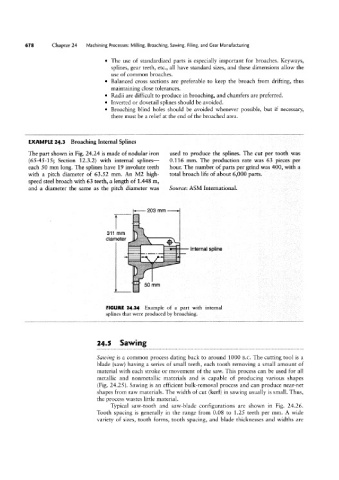

EXAMPLE 24.3 Broaching Internal Splines

The part shown in Fig. 24.24 is made of nodular iron used to produce the splines. The cut per tooth was

(65-45-15; Section 12.3.2) with internal splines- 0.116 mm. The production rate was 63 pieces per

each 50 mm long. The splines have 19 involute teeth hour. The number of parts per grind was 400, with a

with a pitch diameter of 63.52 mm. An M2 high- total broach life of about 6,000 parts.

speed steel broach with 63 teeth, a length of 1.448 m,

and a diameter the same as the pitch diameter was Source: ASM International.

311 mm

diameter 203 mm E Internal spline

T* e

i

‘

% 50 mm

1 .-

FIGURE 24.24 Example of a part with internal

splines that were produced by broaching.

24.5 Sawing

Sawing is a common process dating back to around 1000 B.C. The cutting tool is a

blade (saw) having a series of small teeth, each tooth removing a small amount of

material with each stroke or movement of the saw. This process can be used for all

metallic and nonmetallic materials and is capable of producing various shapes

(Fig. 24.25 ). Sawing is an efficient bulk-removal process and can produce near-net

shapes from ravv materials. The Width of cut (kerf) in sawing usually is small. Thus,

the process Wastes little material.

Typical saw-tooth and saw-blade configurations are shown in Fig. 24.26.

Tooth spacing is generally in the range from 0.08 to 1.25 teeth per mm. A wide

variety of sizes, tooth forms, tooth spacing, and blade thicknesses and widths are