Page 117 - Mechanics of Microelectromechanical Systems

P. 117

104 Chapter 2

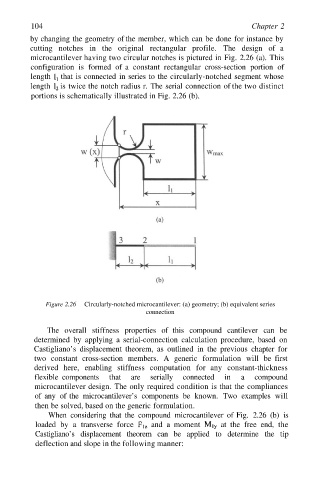

by changing the geometry of the member, which can be done for instance by

cutting notches in the original rectangular profile. The design of a

microcantilever having two circular notches is pictured in Fig. 2.26 (a). This

configuration is formed of a constant rectangular cross-section portion of

length that is connected in series to the circularly-notched segment whose

length is twice the notch radius r. The serial connection of the two distinct

portions is schematically illustrated in Fig. 2.26 (b).

Figure 2.26 Circularly-notched microcantilever: (a) geometry; (b) equivalent series

connection

The overall stiffness properties of this compound cantilever can be

determined by applying a serial-connection calculation procedure, based on

Castigliano’s displacement theorem, as outlined in the previous chapter for

two constant cross-section members. A generic formulation will be first

derived here, enabling stiffness computation for any constant-thickness

flexible components that are serially connected in a compound

microcantilever design. The only required condition is that the compliances

of any of the microcantilever’s components be known. Two examples will

then be solved, based on the generic formulation.

When considering that the compound microcantilever of Fig. 2.26 (b) is

loaded by a transverse force and a moment at the free end, the

Castigliano’s displacement theorem can be applied to determine the tip

deflection and slope in the following manner: