Page 301 - A Practical Guide from Design Planning to Manufacturing

P. 301

Semiconductor Manufacturing 271

As + Mass

AsF gas spectrometer

5

and other ions

e −

Ion source As +

Acceleration

tube

As +

PR PR

N+

diffusion

region

Si wafer

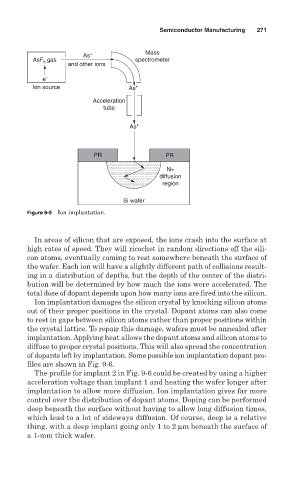

Figure 9-5 Ion implantation.

In areas of silicon that are exposed, the ions crash into the surface at

high rates of speed. They will ricochet in random directions off the sili-

con atoms, eventually coming to rest somewhere beneath the surface of

the wafer. Each ion will have a slightly different path of collisions result-

ing in a distribution of depths, but the depth of the center of the distri-

bution will be determined by how much the ions were accelerated. The

total dose of dopant depends upon how many ions are fired into the silicon.

Ion implantation damages the silicon crystal by knocking silicon atoms

out of their proper positions in the crystal. Dopant atoms can also come

to rest in gaps between silicon atoms rather than proper positions within

the crystal lattice. To repair this damage, wafers must be annealed after

implantation. Applying heat allows the dopant atoms and silicon atoms to

diffuse to proper crystal positions. This will also spread the concentration

of dopants left by implantation. Some possible ion implantation dopant pro-

files are shown in Fig. 9-6.

The profile for implant 2 in Fig. 9-6 could be created by using a higher

acceleration voltage than implant 1 and heating the wafer longer after

implantation to allow more diffusion. Ion implantation gives far more

control over the distribution of dopant atoms. Doping can be performed

deep beneath the surface without having to allow long diffusion times,

which lead to a lot of sideways diffusion. Of course, deep is a relative

thing, with a deep implant going only 1 to 2 µm beneath the surface of

a 1-mm thick wafer.