Page 189 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 189

PROCESSES USING BULK AND SURFACE MICROMACHINING 169

Si wafer

Poly,

Si wafer

(b)

Alignment PSG

window

PSG break line

PSG

Alignment 1

I window

+

p support cantilever

Si wafer

V-groove

(e)

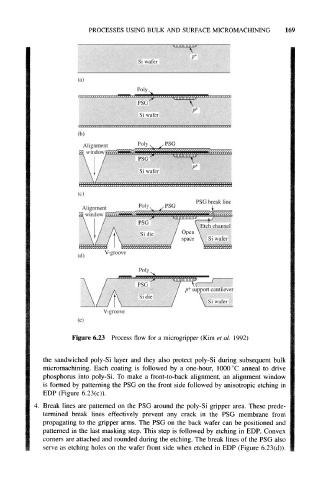

Figure 6.23 Process flow for a microgripper (Kim et al. 1992)

the sandwiched poly-Si layer and they also protect poly-Si during subsequent bulk

micromachining. Each coating is followed by a one-hour, 1000 °C anneal to drive

phosphorus into poly-Si. To make a front-to-back alignment, an alignment window

is formed by patterning the PSG on the front side followed by anisotropic etching in

EDP (Figure 6,23(c)).

4. Break lines are patterned on the PSG around the poly-Si gripper area. These prede-

termined break lines effectively prevent any crack in the PSG membrane from

propagating to the gripper arms. The PSG on the back wafer can be positioned and

patterned in the last masking step. This step is followed by etching in EDP. Convex

corners are attached and rounded during the etching. The break lines of the PSG also

serve as etching holes on the wafer front side when etched in EDP (Figure 6.23(d)).