Page 188 - Microsensors, MEMS and Smart Devices - Gardner Varadhan and Awadelkarim

P. 188

168 SILICON MICROMACHINING: SURFACE

p -support cantilever

Drive arm Extension arm

Si wafer

upport cantilever

Conducting polysilicon lines

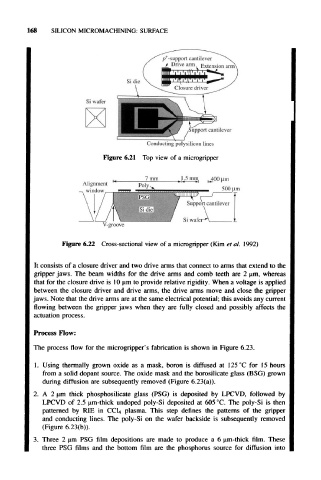

Figure 6.21 Top view of a microgripper

V-groove

Figure 6.22 Cross-sectional view of a microgripper (Kim et al. 1992)

It consists of a closure driver and two drive arms that connect to arms that extend to the

gripper jaws. The beam widths for the drive arms and comb teeth are 2 um, whereas

that for the closure drive is 10 um to provide relative rigidity. When a voltage is applied

between the closure driver and drive arms, the drive arms move and close the gripper

jaws. Note that the drive arms are at the same electrical potential; this avoids any current

flowing between the gripper jaws when they are fully closed and possibly affects the

actuation process.

Process Flow:

The process flow for the microgripper's fabrication is shown in Figure 6.23.

1. Using thermally grown oxide as a mask, boron is diffused at 125 °C for 15 hours

from a solid dopant source. The oxide mask and the borosilicate glass (BSG) grown

during diffusion are subsequently removed (Figure 6.23(a)).

2. A 2 um thick phosphosilicate glass (PSG) is deposited by LPCVD, followed by

LPCVD of 2.5 urn-thick undoped poly-Si deposited at 605 °C. The poly-Si is then

patterned by RIE in CC1 4 plasma. This step defines the patterns of the gripper

and conducting lines. The poly-Si on the wafer backside is subsequently removed

(Figure 6.23(b)).

3. Three 2 um PSG film depositions are made to produce a 6 urn-thick film. These

three PSG films and the bottom film are the phosphorus source for diffusion into