Page 90 - Book Hosokawa Nanoparticle Technology Handbook

P. 90

FUNDAMENTALS CH. 2 STRUCTURAL CONTROL OF NANOPARTICLES

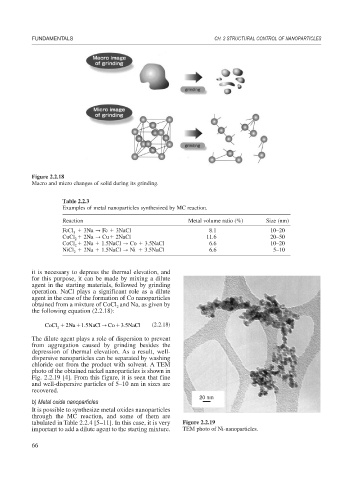

Figure 2.2.18

Macro and micro changes of solid during its grinding.

Table 2.2.3

Examples of metal nanoparticles synthesized by MC reaction.

Reaction Metal volume ratio (%) Size (nm)

FeCl 3Na Fe 3NaCl 8.1 10–20

3

CuCl 2Na Cu 2NaCl 11.6 20–50

2

CoCl 2Na 1.5NaCl Co 3.5NaCl 6.6 10–20

2

NiCl 2Na 1.5NaCl Ni 3.5NaCl 6.6 5–10

2

it is necessary to depress the thermal elevation, and

for this purpose, it can be made by mixing a dilute

agent in the starting materials, followed by grinding

operation. NaCl plays a significant role as a dilute

agent in the case of the formation of Co nanoparticles

obtained from a mixture of CoCl and Na, as given by

2

the following equation (2.2.18):

CoCl 2Na 1.5NaCl Co 3.5NaCl (2.2.18)

2

The dilute agent plays a role of dispersion to prevent

from aggregation caused by grinding besides the

depression of thermal elevation. As a result, well-

dispersive nanoparticles can be separated by washing

chloride out from the product with solvent. A TEM

photo of the obtained nickel nanoparticles is shown in

Fig. 2.2.19 [4]. From this figure, it is seen that fine

and well-dispersive particles of 5–10 nm in sizes are

recovered.

20 nm

b) Metal oxide nanoparticles

It is possible to synthesize metal oxides nanoparticles

through the MC reaction, and some of them are

tabulated in Table 2.2.4 [5–11]. In this case, it is very Figure 2.2.19

important to add a dilute agent to the starting mixture. TEM photo of Ni-nanoparticles.

66