Page 91 - Book Hosokawa Nanoparticle Technology Handbook

P. 91

2.2 PARTICLE SIZE FUNDAMENTALS

Table 2.2.4

Examples of metal oxide nanoparticles synthesized by MC

reaction.

Starting mixtures Reaction products

2AlCl 3 CaO Al O 3CaCl 2

2

3

ZrCl 4 2CaO ZrO 2CaCl 2

2

GdCl 3 3NaOH Gd O 3NaCl 1.5H O

3

2

2

CeCl 3 NaOH CeO 3NaCl H O

2

2

Na Cr O S Cr O Na SO 4

3

7

2

2

2

2

2NbCl 5 5Na CO 3 Nb O 10NaCl 5CO 2

2

2

5

SnCl 2 Na CO O SnO 2NaCl CO 2

3

2

2

2

2FeCl 3 3Ca(OH) 2 Fe O 3CaCl 2 3H O

2

3

2

ZnCl 2 Na CO 3 ZnO 2NaCl CO 2

2

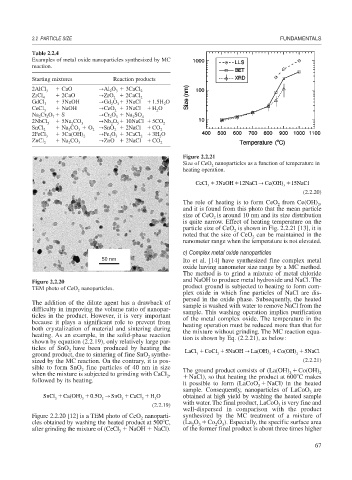

Figure 2.2.21

Size of CeO nanoparticles as a function of temperature in

2

heating operation.

CeCl 3NaOH 12NaCl Ce(OH) 15NaCl

3 3

(2.2.20)

The role of heating is to form CeO from Ce(OH) ,

2

3

and it is found from this photo that the mean particle

size of CeO is around 10 nm and its size distribution

2

is quite narrow. Effect of heating temperature on the

particle size of CeO is shown in Fig. 2.2.21 [13], it is

2

noted that the size of CeO can be maintained in the

2

nanometer range when the temperature is not elevated.

c) Complex metal oxide nanoparticles

50 nm Ito et al. [14] have synthesized fine complex metal

oxide having nanometer size range by a MC method.

The method is to grind a mixture of metal chloride

and NaOH to produce metal hydroxide and NaCl. The

Figure 2.2.20

TEM photo of CeO nanoparticles. product ground is subjected to heating to form com-

2

plex oxide in which fine particles of NaCl are dis-

persed in the oxide phase. Subsequently, the heated

The addition of the dilute agent has a drawback of sample is washed with water to remove NaCl from the

difficulty in improving the volume ratio of nanopar- sample. This washing operation implies purification

ticles in the product. However, it is very important of the metal complex oxide. The temperature in the

because it plays a significant role to prevent from heating operation must be reduced more than that for

both crystalization of material and sintering during the mixture without grinding. The MC reaction equa-

heating. As an example, in the solid-phase reaction tion is shown by Eq. (2.2.21), as below:

shown by equation (2.2.19), only relatively large par-

ticles of SnO have been produced by heating the LaCl CoCl 5NaOH La(OH) Co(OH) 5NaCl

2

ground product, due to sintering of fine SnO synthe- 3 2 3 2

2

sized by the MC reaction. On the contrary, it is pos- (2.2.21)

sible to form SnO fine particles of 40 nm in size The ground product consists of (La(OH) Co(OH)

2

when the mixture is subjected to grinding with CaCl , NaCl), so that heating the product at 600 C makes 2

3

2

followed by its heating.

it possible to form (LaCoO NaCl) in the heated

3

sample. Consequently, nanoparticles of LaCoO are

3

SnCl Ca(OH) 0.5O SnO CaCl H O obtained at high yield by washing the heated sample

2 2 2 2 2 2

with water. The final product, LaCoO is very fine and

(2.2.19) 3

well-dispersed in comparison with the product

Figure 2.2.20 [12] is a TEM photo of CeO nanoparti- synthesized by the MC treatment of a mixture of

2

cles obtained by washing the heated product at 500 C, (La O Co O ). Especially, the specific surface area

3

2

2

3

after grinding the mixture of (CeCl NaOH NaCl). of the former final product is about three times higher

3

67