Page 197 - Plant design and economics for chemical engineers

P. 197

COST ESTIMATION 171

From Table 5, the equipment vs. capacity exponent is given as 0.54:

(798)( NO)o.54

In 1986, cost of reactor = ($8350) 721

= $24,300

Purchased-equipment costs for vessels, tanks, and process- and materials-

handling equipment can often be estimated on the basis of weight. The fact that

a wide variety of types of equipment have about the same cost per unit weight is

quite useful, particularly when other cost data are not available. Generally, the

cost data generated by this method are sufficiently reliable to permit order-of-

magnitude estimates.

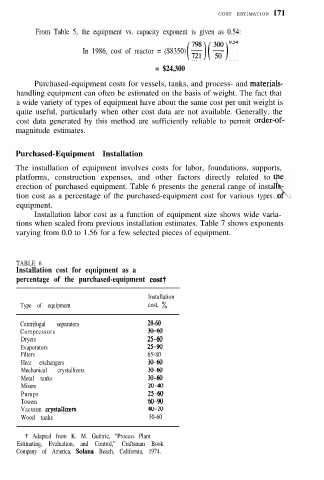

Purchased-Equipment Installation

The installation of equipment involves costs for labor, foundations, supports,

platforms, construction expenses, and other factors directly related to he

erection of purchased equipment. Table 6 presents the general range of install -

o

tion cost as a percentage of the purchased-equipment cost for various types !i

equipment.

Installation labor cost as a function of equipment size shows wide varia-

tions when scaled from previous installation estimates. Table 7 shows exponents

varying from 0.0 to 1.56 for a few selected pieces of equipment.

TABLE 6

Installation cost for equipment as a

percentage of the purchased-equipment cost?

Installation

Type of equipment cost, %

Centrifugal separators 20-60

Compressors 30-60

Dryers 25-60

Evaporators 25-90

Filters 65-80

Heat exchangers 3C-60

Mechanical crystallizers 3WXl

Metal tanks 30-60

Mixers 20-40

Pumps 25-60

Towers 60-90

Vacuum crystailizers 40-70

Wood tanks 30-60

t Adapted from K. M. Guthrie, “Process Plant

Estimating, Evaluation, and Control,” Craftsman Book

Company of America, Solana Beach, California, 1974.