Page 385 - Power Electronics Handbook

P. 385

Electrical machine control 375

Feedback current slqnal

1

Converter current

Converter 2

I

feedback speed siqnal

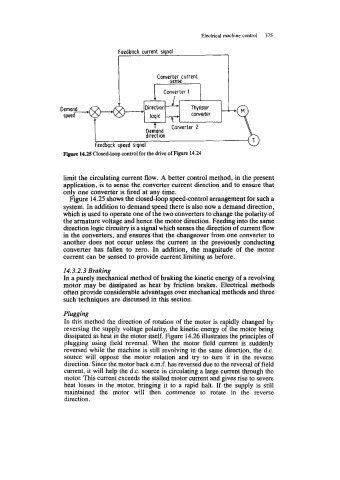

Figure 14.25 Closed-loop control for the drive of Figure 14.24

limit the circulating current flow. A better control method, in the present

application, is to sense the converter current direction and to ensure that

only one converter is fired at any time.

Figure 14.25 shows the closed-loop speed-control arrangement for such a

system. In addition to demand speed there is also now a demand direction,

which is used to operate one of the two converters to change the polarity of

the armature voltage and hence the motor direction. Feeding into the same

direction logic circuitry is a signal which senses the direction of current flow

in the converters, and ensures that the changeover from one converter to

another does not occur unless the current in the previously conducting

converter has fallen to zero. In addition, the magnitude of the motor

current can be sensed to provide current limiting as before.

14.3.2.3 Braking

In a purely mechanical method of braking the kinetic energy of a revolving

motor may be dissipated as heat by friction brakes. Electrical methods

often provide considerable advantages over mechanical methods and three

such techniques are discussed in this section.

Plugging

In this method the direction of rotation of the motor is rapidly changed by

reversing the supply voltage polarity, the kinetic energy of the motor being

dissipated as heat in the motor itself. Figure 14.26 illustrates the principles of

plugging using field reversal. When the motor field current is suddenly

reversed while the machine is still revolving in the same direction, the d.c.

source will oppose the motor rotation and try to turn it in the reverse

direction. Since the motor back e.m.f. has reversed due to the reversal of field

current, it will help the d.c. source in circulating a large current through the

motor. This current exceeds the stalled motor current and gives rise to severe

heat losses in the motor, bringing it to a rapid halt. If the supply is still

maintained the motor will then commence to rotate in the reverse

direction.