Page 386 - Power Electronics Handbook

P. 386

376 Power semiconductor circuit applications

c r

*-A *bB

-- --

-

-

+

+

--

-

-

"B "El

a. B **A

- -

(a) (b)

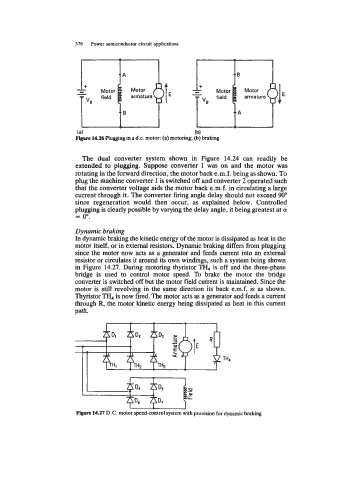

Figwe 14.26 Plugging in a d.c. motor: (a) motoring; (b) braking

The dual converter system shown in Figure 14.24 can readily be

extended to plugging. Suppose converter 1 was on and the motor was

rotating in the forward direction, the motor back e.m.f. being as shown. To

plug the machine converter 1 is switched off and converter 2 operated such

that the converter voltage aids the motor back e.m.f. in circulating a large

current through it. The converter firing angle delay should not exceed 90"

since regeneration would then occur, as explained below. Controlled

plugging is clearly possible by varying the delay angle, it being greatest at ci

= 0".

Dynamic braking

In dynamic braking the kinetic energy of the motor is dissipated as heat in the

motor itself, or in external resistors. Dynamic braking differs from plugging

since the motor now acts as a generator and feeds current into an external

resistor or circulates it around its own windings, such a system being shown

in Figure 14.27. During motoring thyristor TH, is off and the three-phase

bridge is used to control motor speed. To brake the motor the bridge

converter is switched off but the motor field current is maintained. Since the

motor is still revolving in the same direction its back e.m.f. is as shown.

Thyristor TH, is now fired. The motor acts as a generator and feeds a current

through R, the motor kinetic energy being dissipated as heat in this current

path.

Figure 14.27 D.C. motor speed-control system with provision for dynamic braking