Page 381 - Power Electronics Handbook

P. 381

Electrical machine control 371

Although a tachogenerator has been shown in Figure 14.19 as providing

the feedback speed signal, it is not the only system that can be used. For

instance, equations (14.1) and (14.2) indicate that the motor speed is

proportional to the supply voltage provided allowance is made for the drop

in the motor armature resistance. Since this resistance can be measured, all

that is required is a knowledge of the armature current at any supply

voltage. Therefore the feedback speed signal can be made proportional to

the supply voltage on which is superimposed an I,R drop compensation

signal. Since this signal is proportional to armature current it may also be

used in the current limit loop if required.

For a certain load torque, motor speed will be such that the resultant

current interacting with the field will give a machine torque just sufficient

to overcome the load, plus internal losses. Speed control is therefore a

form of torque control. In a d.c. motor, if the armature voltage is reduced,

but the load torque kept constant, speed will fall so that the back e.m.f.

reduces sufficiently to increase the current to almost its original value (flux

being kept constant) and give an unchanged machine torque. Similarly, a

reduction in field flux would cause a reduction in speed so that the

increased current can give the same torque, the flux-current product

tending to be maintained constant. If the load torque was allowed to fall as

flux decreased, motor speed would increase to compensate for lost torque

and so keep the power constant.

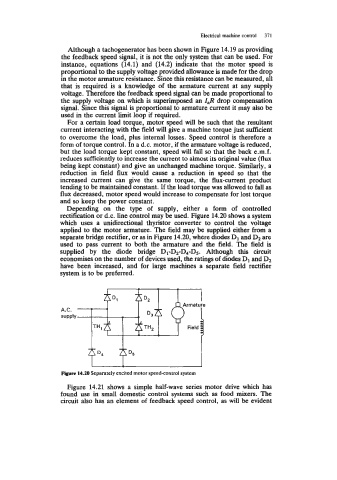

Depending on the type of supply, either a form of controlled

rectification or d.c. line control may be used. Figure 14.20 shows a system

which uses a unidirectional thyristor converter to control the voltage

applied to the motor armature. The field may be supplied either from a

separate bridge rectifier, or as in Figure 14.20, where diodes D1 and D2 are

used to pass current to both the armature and the field. The field is

supplied by the diode bridge D~-D~-D~-Ds. Although this circuit

economises on the number of devices used, the ratings of diodes D1 and D2

have been increased, and for large machines a separate field rectifier

system is to be preferred.

Figure 14.20 Separately excited motor speed-control system

Figure 14.21 shows a simple half-wave series motor drive which has

found use in small domestic control systems such as food mixers. The

circuit also has an element of feedback speed control, as will be evident