Page 188 - Practical Control Engineering a Guide for Engineers, Managers, and Practitioners

P. 188

11 llllerll••~tell Precess 113

I 25~--~----~-----r----~----~--~

2

1i 1~ •••••• . . ········'·················

l 0.: :.:::::t:::::::l::::::::J~~-~~.1:::::::

0

i ~~ ro ~ ~ ~ ~ M

10

~

j.

g 5

...

&

I 0

u

Tune

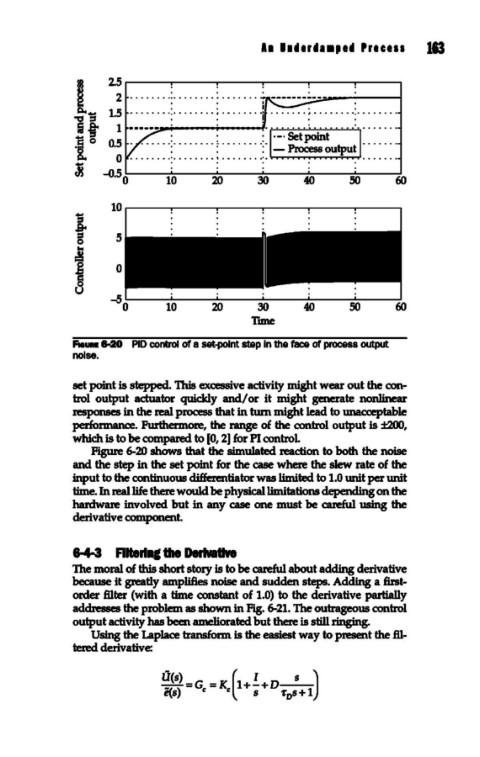

Aa .. 8-20 PID control of a set-point step In the face of process output

noise.

set point is stepped. This excessive activity might wear out the con-

trol output actuator quickly and/ or it might generate nonlinear

responses in the real process that in tum might lead to unacceptable

performance. Furthermore, the range of the control output is ±200,

which is to be compared to [0, 2] for PI controL

Figure 6-20 shows that the simulated reaction to both the noise

and the step in the set point for the case where the slew rate of the

input to the continuous differentiator was limited to 1.0 unit per unit

time. In real life there would be physical limitations depending on the

hardware involved but in any case one must be careful using the

derivative component.

8-4-3 RlterlnJ tile Derivative

The moral of this short story is to be careful about adding derivative

because it greatly amplifies noise and sudden steps. Adding a first-

Older filter (with a time constant of 1.0) to the derivative partially

addresses the problem as shown in Fig. 6-21. The outrageous control

output activity has been ameliorated but there is still ringing.

Using the Laplace transform is the easiest way to present the fil-

tered derivative:

U(s) ( I s )

_() =Gc: =Kc: 1+-+D--

e s s -r s+ 1

0