Page 203 - Semiconductor Manufacturing Handbook

P. 203

Geng(SMH)_CH14.qxd 04/04/2005 19:52 Page 14.4

CHEMICAL VAPOR DEPOSITION

14.4 WAFER PROCESSING

Does it matter if the process is kinetically controlled or mass-transfer limited? Yes. When mass-

transfer limited, the surface is starved for at least one of the reactants. That means the sticking coef-

ficient for that reactant will be high. As we will see later in the chapter, high sticking coefficients

result in poor step coverage. On the other hand, in the kinetic regime, the surface is saturated with

reactants. Under these conditions, by-products can become trapped in the film, reducing its purity.

In the case of the tungsten reaction, the level of fluorine incorporated into the film is much higher

when the process is kinetically controlled.

Gas Utilization. For many CVD processes, reactants are expensive and so we want to use them

most efficiently. Unfortunately, the most efficient operating conditions are those that produce the

lowest deposition rate, i.e., flow the gases into the chamber very slowly, to allow lots of time for the

reactants to diffuse to the wafer.

Mass-transfer limited processes will be more efficient than kinetically controlled ones. The low

sticking probabilities of kinetically controlled processes mean that some molecules will hit the

wafer, bounce off, and be pumped out. The utilization can be easily calculated if you know the flow

and deposition rates.

Transport Mechanisms: Diffusion, Convection, Thermal Diffusion, E Fields, Pe Number.

Reactants are transported from the inlet to the wafer primarily by convection and diffusion. Several

secondary mechanisms may also be present. In convection, the reactants are transported by the gas

velocity. In diffusive transport, the reactants migrate from areas of high concentration to low. The

rate of convective transport is given by

j = Y ρu

i

where Y is the mass fraction of species i, r is the density of the gas, and u is the velocity. The dif-

i

fusive flux is given by

j =− Dρ∇Y

i

where D is the diffusion coefficient of species i in the mixture. The relative importance of convec-

tion and diffusion is determined by the dimensionless Peclet number

Pe = ud

D

where d is the characteristic length of the chamber (typically the distance from showerhead to wafer).

If Pe << 1, the transport is primarily by diffusion. If Pe >> 1, it is by convection. For most CVD reac-

tors, Pe is between 1 and 10, indicating that convection is somewhat stronger, but both mechanisms

are important. This can have implications for process development. For instance, if a process engi-

neer changes a carrier gas from helium to argon, as a cost-saving measure, there will likely be the

unintended consequence of lowering the deposition rate because of the lower diffusivity of argon.

Diffusive transport can also lead to nonuniformities when there are purge flows near the wafer sur-

face. The reactants diffuse out of the reaction zone, following the concentration gradient, leading to

a thin deposition at the wafer edge.

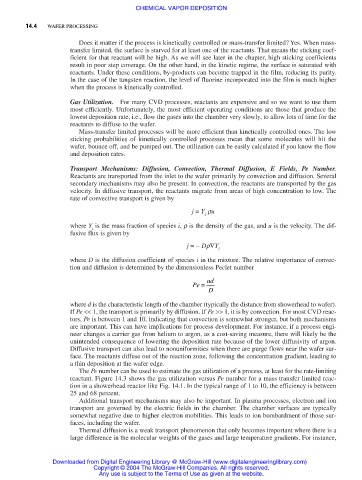

The Pe number can be used to estimate the gas utilization of a process, at least for the rate-limiting

reactant. Figure 14.3 shows the gas utilization versus Pe number for a mass transfer limited reac-

tion in a showerhead reactor like Fig. 14.1. In the typical range of 1 to 10, the efficiency is between

25 and 68 percent.

Additional transport mechanisms may also be important. In plasma processes, electron and ion

transport are governed by the electric fields in the chamber. The chamber surfaces are typically

somewhat negative due to higher electron mobilities. This leads to ion bombardment of those sur-

faces, including the wafer.

Thermal diffusion is a weak transport phenomenon that only becomes important where there is a

large difference in the molecular weights of the gases and large temperature gradients. For instance,

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.