Page 237 - Semiconductor Manufacturing Handbook

P. 237

Geng(SMH)_CH16.qxd 04/04/2005 19:54 Page 16.4

ECD FUNDAMENTALS

16.4 WAFER PROCESSING

current density (Fig. 16.2) in order to produce smooth deposits with consistent morphology. Limiting

current density is a reasonable measure of the relative deposition speed capability of different sys-

tems. The factors that increase the diffusion rate of metal ions to the cathode surface have the most

impact on increasing the limiting current density of an ECD system. These factors are agitation (such

as flow and spin speed), temperature, and metal ion concentration.

Superconformal deposition is the deposition property that enabled electrolytic deposition

processes to be utilized for copper deposition in a damascene metallization scheme. 7–10 This is the

ability of the process to provide a higher deposition rate, or coverage, at the bottom of an etched fea-

ture than in the field region on top. This property, which results from the combination of suppressors

and accelerators in the bath, 11,12 enables the process to be used to fill high-aspect-ratio features with

subconformal PVD seed layers. Extensive references are available on the two theories that explain this

behavior—consumption of diffusion-limited suppressing agents and curvature-enhanced catalytic

enhancement. 7–9,13,14

Copper can be electrolytically deposited from several types of solutions—acidic copper sulfate,

methane sulfonic acid, basic cyanide complexed chemistries, pyrophosphate baths, and many other

specialized chemistries; some of which contain complexing agents. Most copper deposition for

semiconductor processing, however, is done using relatively simple acidic copper sulfate chemistry.

These baths typically consist of three inorganic components—sulfuric acid, copper sulfate, and

hydrochloric acid—with some organic compounds to modify the deposition and film properties. These

organic additives are usually named after their functions, with names such as suppressors, accelerators,

and levelers.

Copper sulfate provides the source of copper ions that are electrolytically deposited during the

plating operation. The higher the concentration of copper ions in solution, the better the feature-

filling performance of the chemistry. Sulfuric acid is used to maintain an acid environment to keep

+

copper in solution and to provide the ionic conductivity of the solution. The H ions, or protons, are

the preferred charge carriers in the solution and provide high solution conductivity. The pH of the

solution also affects the activity of the organic additives. The concentrations of copper sulfate and

sulfuric acid are not completely independent since the common ion effect limits the total solution

15

concentration of sulfate ion. This sets the upper limit on the total concentration of these two chem-

icals. Hydrochloric acid is added to these solutions to assist the effectiveness of some organic addi-

tives and to aid in anode erosion. 13,16 Table 16.1 lists examples of acid copper plating baths with

varying characteristics.

The organic additives most commonly used in acid copper sulfate plating baths consist of sup-

pressors, accelerators, and levelers. Suppressors typically consist of polymers or copolymers of gly-

col ether compounds. 16,17 These organic materials tend to adsorb on the copper surface and inhibit

deposition, although they usually require the presence of a small amount of chloride ion to be effec-

tive. They are called suppressors because of their effect on reducing the deposition rate (current den-

sity) at a given deposition potential. They also have the effect of increasing the overpotential required

for maintaining a specific deposition rate. Conversely, there are classes of materials which, when

added to a bath containing suppressors, increase the deposition rate or decrease the overpotential to

maintain a specific deposition rate. These accelerators are typically compounds such as 3-mercapto-

1-propanesulfonate (MPS) and bis (3-sulfopropyl) disulfide (SPS), or similar thiol compounds. 16,17

These materials usually provide a catalytic effect and remain adsorbed at the deposition surface as

the deposition proceeds. The geometric concentration of these materials on the surface within cavities

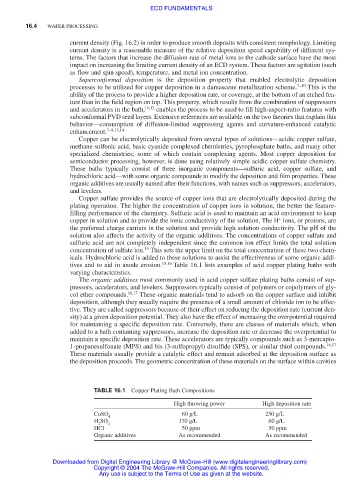

TABLE 16.1 Copper Plating Bath Compositions

High throwing power High deposition rate

CuSO 60 g/L 250 g/L

4

H SO 170 g/L 60 g/L

2 4

HCl 50 ppm 50 ppm

Organic additives As recommended As recommended

Downloaded from Digital Engineering Library @ McGraw-Hill (www.digitalengineeringlibrary.com)

Copyright © 2004 The McGraw-Hill Companies. All rights reserved.

Any use is subject to the Terms of Use as given at the website.