Page 188 - Separation process principles 2

P. 188

Exercises 153

(a) At what temperature does vaporization begin?

Equilibrium liquid Exit equilibrium vapor (b) What is the composition of the first bubble of equilibrium

>

from another stage Tv, Pv, Y, vapor formed?

(c) What is the composition of the residual liquid when 25 mol%

has evaporated? Assume that all vapor formed is retained within the

apparatus and that it is completely mixed and in equilibrium with

Feed vapor L'

the residual liquid.

Equilibrium Exit equilibrium

stage liquid phase * (d) Repeat part (c) for 90 mol% vaporized.

Feed liquid T,,', P:, xi1 (e) Repeat part (d) if, after 25 mol% is vaporized as in part (c), the

vapor formed is removed and an additional 35 mol% is vaporized

by the same technique used in part (c).

(f) Plot the temperature versus the percent vaporized for parts (c)

LIT and (e).

Equilibrium vapor Exit equilibrium (g) Use the following vapor pressure data in conjunction with

from another stage liquid phase II - Raoult's and Dalton's laws to construct a T-x-y diagram, and

r

T,", P,", x," compare it for the answers obtained in parts (a) and (f) wit11 those

Q

obtained using the experimental T-x-y data. What do you con-

Heat to clude about the applicability of Raoult's law to this binary

(+) or from (-) system?

the stage

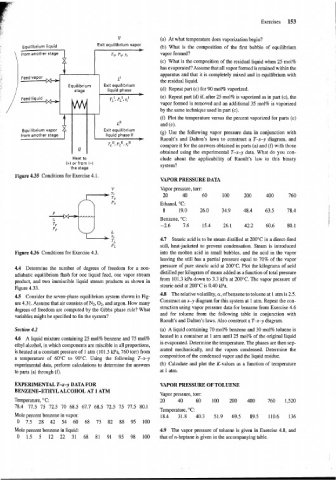

Figure 4.35 Conditions for Exercise 4.1.

VAPOR PRESSURE DATA

Vapor pressure, torr:

20 40 60 100 200 400 760

Ethanol, "C:

8 19.0 26.0 34.9 48.4 63.5 78.4

Benzene, "C:

-2.6 7.6 15.4 26.1 42.2 60.6 80.1

4.7 Stearic acid is to be steam distilled at 200°C in a direct-fired

'.

PL still, heat-jacketed to prevent condensation. Steam is introduced

Figure 4.36 Conditions for Exercise 4.3. into the molten acid in small bubbles, and the acid in the vapor

leaving the still has a partial pressure equal to 70% of the vapor

pressure of pure stearic acid at 200°C. Plot the kilograms of acid

4.4 Determine the number of degrees of freedom for a non-

distilled per kilogram of steam added as a function of total pressure

adiabatic equilibrium flash for one liquid feed, one vapor stream

from 101.3 kPa down to 3.3 kPa at 200°C. The vapor pressure of

product, and two immiscible liquid stream products as shown in

stearic acid at 200°C is 0.40 kPa.

Figure 4.33.

4.8 The relative volatility, a, of benzene to toluene at 1 atm is 2.5.

4.5 Consider the seven-phase equilibrium system shown in Fig-

Construct an x-y diagram for this system at 1 atm. Repeat the con-

ure 4.3 1. Assume that air consists of N2, 02, and argon. How many

struction using vapor pressure data for benzene from Exercise 4.6

degrees of freedom are computed by the Gibbs phase rule? What

and for toluene from the following table in conjunction with

variables might be specified to fix the system?

Raoult's and Dalton's laws. Also construct a T-x-y diagram.

Section 4.2 (a) A liquid containing 70 mol% benzene and 30 mol% toluene is

heated in a container at 1 atm until 25 mol% of the original liquid

4.6 A liquid mixture containing 25 mol% benzene and 75 mol%

is evaporated. Determine the temperature. The phases are then sep-

ethyl alcohol, in which components are miscible in all proportions,

arated mechanically, and the vapors condensed. Determine the

is heated at a constant pressure of 1 atm (101.3 kPa, 760 ton) from

composition of the condensed vapor and the liquid residue.

a temperature of 60°C to 90°C. Using the following T-x-y

experimental data, perform calculations to determine the answers (b) Calculate and plot the K-values as a function of temperature

to parts (a) through (f). at 1 atm.

EXPERIMENTAL T-X-y DATA FOR VAPOR PRESSURE OF TOLUENE

BENZENE-ETHYL ALCOHOL AT 1 ATM

Vapor pressure, torr:

Temperature, "C: 20 40 60 100 200 400 760 1,520

78.4 77.5 75 72.5 70 68.5 67.7 68.5 72.5 75 77.5 80.1

Temperature, "C:

Mole percent benzene in vapor: 18.4 31.8 40.3 51.9 69.5 89.5 110.6 136

0 7.5 28 42 54 60 68 73 82 88 95 100

Mole percent benzene in liquid: 4.9 The vapor pressure of toluene is given in Exercise 4.8, and

0 1.5 5 12 22 31 68 81 91 95 98 100 that of n-heptane is given in the accompanying table.