Page 197 - Separation process principles 2

P. 197

162 Chapter 5 Cascades and Hybrid Systems

Feed Product 1 easier to apply in a batchwise manner. It differs from the

I countercurrent cascade in that the solvent is divided into

portions fed individually to each stage.

Stage

1 A complex diamond variation of the crosscurrent cascade

4 t is shown in Figure 5.2~. Unlike the two former cascades,

which are linear or one-dimensional, the diamond configura-

Stage tion is two-dimensional. One application is to batch crystal-

2 lization. Feed F is separated in stage 1 into crystals, which

t pass to stage 2, and mother liquor, which passes to stage 4.

In each of the other stages, partial crystallization or recrys-

tallization occurs by processing crystals, mother liquor, or

combinations of the two. Final products are p~~rified crystals

E and impurity-bearing mother liquors.

The first three cascades in Figure 5.2 consist of single

Stage

product 2 1 Mass-separating sections with streams entering and leaving only from the

ends. Such cascades are used to recover components from a

feed stream and are not generally useful for making a sharp

agent

separation between two selected feed components, called

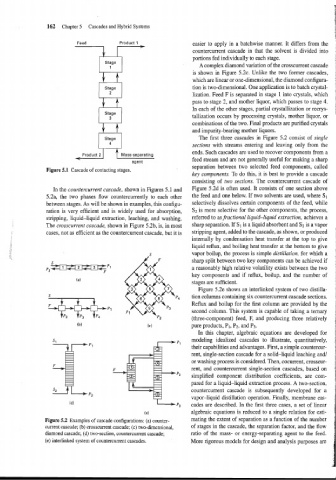

Figure 5.1 Cascade of contacting stages.

key components. To do this, it is best to provide a cascade

consisting of two sections. The countercurrent cascade of

In the countercurrent cascade, shown in Figures 5.1 and Figure 5.2d is often used. It consists of one section above

5.2a, the two phases flow countercurrently to each other the feed and one below. If two solvents are used, where S1

between stages. As will be shown in examples, this configu- selectively dissolves certain components of the feed, while

ration is very efficient and is widely used for absorption, S2 is more selective for the other components, the process,

stripping, liquid-liquid extraction, leaching, and washing. referred to as fractional liquid-liquid extraction, achieves a

The crosscurrent cascade, shown in Figure 5.2b, is, in most sharp separation. If S is a liquid absorbent and Sz is a vapor

cases, not as efficient as the countercurrent cascade, but it is stripping agent, added to the cascade, as shown, or produced

internally by condensation heat transfer at the top to give

liquid reflux, and boiling heat transfer at the bottom to give

vapor boilup, the process is simple distillation, for which a

sharp split between two key components can be achieved if

a reasonably high relative volatility exists between the two

key components and if reflux, boilup, and the number of

stages are sufficient.

Figure 5.2e shows an interlinked system of two distilla-

tion columns containing six countercurrent cascade sections.

Reflux and boilup for the first column are provided by the

second column. This system is capable of taking a ternary

(three-component) feed, F, and producing three relatively

pure products, PI, P2, and P3.

In this chapter, algebraic equations are developed for

modeling idealized cascades to illustrate, quantitatively,

their capabilities and advantages. First, a simple countercur-

rent, single-section cascade for a solid-liquid leaching and/

or washing process is considered. Then, cocurrent, crosscur-

rent, and countercurrent single-section cascades, based on

simplified component distribution coefficients, are com-

pared for a liquid-liquid extraction process. A two-section,

countercurrent cascade is subsequently developed for a

vapor-liquid distillation operation. Finally, membrane cas-

cades are described. In the first three cases, a set of linear

algebraic equations is reduced to a single relation for esti-

(e)

Figure 5.2 Examples of cascade configurations: (a) counter- mating the extent of separation as a function of the number

current cascade; (b) crosscurrent cascade; (c) two-dimensional, of stages in the cascade, the separation factor, and the flow

diamond cascade; (d) two-section, countercurrent cascade; ratio of the mass- or energy-separating agent to the feed.

(e) interlinked system of countercurrent cascades. More rigorous models for design and analysis purposes are