Page 477 - Shigley's Mechanical Engineering Design

P. 477

bud29281_ch08_409-474.qxd 12/16/2009 7:11 pm Page 452 pinnacle 203:MHDQ196:bud29281:0073529281:bud29281_pagefiles:

452 Mechanical Engineering Design

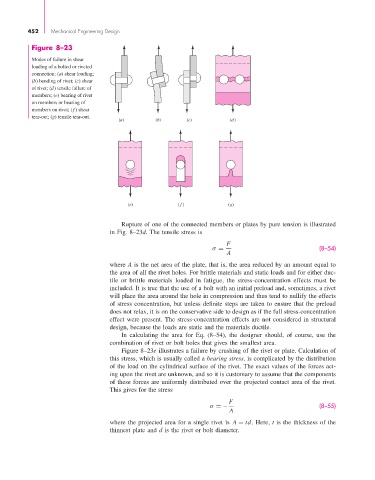

Figure 8–23

Modes of failure in shear

loading of a bolted or riveted

connection: (a) shear loading;

(b) bending of rivet; (c) shear

of rivet; (d) tensile failure of

members; (e) bearing of rivet

on members or bearing of

members on rivet; (f) shear

tear-out; (g) tensile tear-out.

(a) (b) (c) (d)

(e) ( f ) (g)

Rupture of one of the connected members or plates by pure tension is illustrated

in Fig. 8–23d. The tensile stress is

F

σ = (8–54)

A

where A is the net area of the plate, that is, the area reduced by an amount equal to

the area of all the rivet holes. For brittle materials and static loads and for either duc-

tile or brittle materials loaded in fatigue, the stress-concentration effects must be

included. It is true that the use of a bolt with an initial preload and, sometimes, a rivet

will place the area around the hole in compression and thus tend to nullify the effects

of stress concentration, but unless definite steps are taken to ensure that the preload

does not relax, it is on the conservative side to design as if the full stress-concentration

effect were present. The stress-concentration effects are not considered in structural

design, because the loads are static and the materials ductile.

In calculating the area for Eq. (8–54), the designer should, of course, use the

combination of rivet or bolt holes that gives the smallest area.

Figure 8–23e illustrates a failure by crushing of the rivet or plate. Calculation of

this stress, which is usually called a bearing stress, is complicated by the distribution

of the load on the cylindrical surface of the rivet. The exact values of the forces act-

ing upon the rivet are unknown, and so it is customary to assume that the components

of these forces are uniformly distributed over the projected contact area of the rivet.

This gives for the stress

F

σ =− (8–55)

A

where the projected area for a single rivet is A = td. Here, t is the thickness of the

thinnest plate and d is the rivet or bolt diameter.