Page 304 - Solid Waste Analysis and Minimization a Systems Approach

P. 304

282 SOLID WASTE ESTIMATION AND PREDICTION

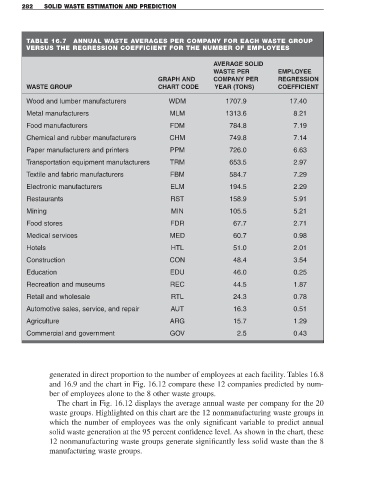

TABLE 16.7 ANNUAL WASTE AVERAGES PER COMPANY FOR EACH WASTE GROUP

VERSUS THE REGRESSION COEFFICIENT FOR THE NUMBER OF EMPLOYEES

AVERAGE SOLID

WASTE PER EMPLOYEE

GRAPH AND COMPANY PER REGRESSION

WASTE GROUP CHART CODE YEAR (TONS) COEFFICIENT

Wood and lumber manufacturers WDM 1707.9 17.40

Metal manufacturers MLM 1313.6 8.21

Food manufacturers FDM 784.8 7.19

Chemical and rubber manufacturers CHM 749.8 7.14

Paper manufacturers and printers PPM 726.0 6.63

Transportation equipment manufacturers TRM 653.5 2.97

Textile and fabric manufacturers FBM 584.7 7.29

Electronic manufacturers ELM 194.5 2.29

Restaurants RST 158.9 5.91

Mining MIN 105.5 5.21

Food stores FDR 67.7 2.71

Medical services MED 60.7 0.98

Hotels HTL 51.0 2.01

Construction CON 48.4 3.54

Education EDU 46.0 0.25

Recreation and museums REC 44.5 1.87

Retail and wholesale RTL 24.3 0.78

Automotive sales, service, and repair AUT 16.3 0.51

Agriculture ARG 15.7 1.29

Commercial and government GOV 2.5 0.43

generated in direct proportion to the number of employees at each facility. Tables 16.8

and 16.9 and the chart in Fig. 16.12 compare these 12 companies predicted by num-

ber of employees alone to the 8 other waste groups.

The chart in Fig. 16.12 displays the average annual waste per company for the 20

waste groups. Highlighted on this chart are the 12 nonmanufacturing waste groups in

which the number of employees was the only significant variable to predict annual

solid waste generation at the 95 percent confidence level. As shown in the chart, these

12 nonmanufacturing waste groups generate significantly less solid waste than the 8

manufacturing waste groups.