Page 250 - Sustainability in the Process Industry Integration and Optimization

P. 250

E x a m p l e s a n d Ca s e S t u d i e s 227

Stream name Supply temp. [°C] Target temp. [°C] ΔH [kW]

A1 50 140 450

A2 100 30 420

A3 100 140 80

TABLE 10.5 Data for Process A (Problem 3)

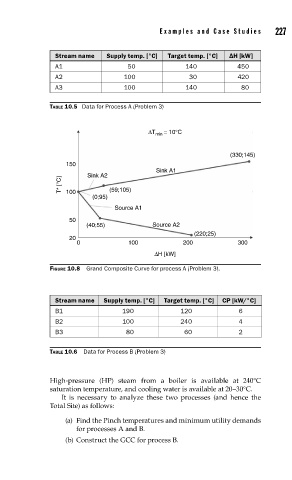

ΔT min = 10°C

(330;145)

150

Sink A1

Sink A2

T* [°C] (59;105)

100

(0;95)

Source A1

50

(40;55) Source A2

(220;25)

20

0 100 200 300

ΔH [kW]

FIGURE 10.8 Grand Composite Curve for process A (Problem 3).

Stream name Supply temp. [°C] Target temp. [°C] CP [kW/°C]

B1 190 120 6

B2 100 240 4

B3 80 60 2

TABLE 10.6 Data for Process B (Problem 3)

High-pressure (HP) steam from a boiler is available at 240°C

saturation temperature, and cooling water is available at 20–30°C.

It is necessary to analyze these two processes (and hence the

Total Site) as follows:

(a) Find the Pinch temperatures and minimum utility demands

for processes A and B.

(b) Construct the GCC for process B.