Page 252 - Sustainability in the Process Industry Integration and Optimization

P. 252

E x a m p l e s a n d Ca s e S t u d i e s 229

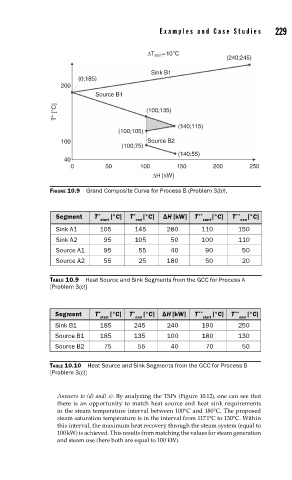

ΔT min =10°C

(240;245)

Sink B1

(0;185)

200

Source B1

T* [°C] (100;135)

(140;115)

(100;105)

100 Source B2

(100;75)

(140;55)

40

0 50 100 150 200 250

ΔH [kW]

FIGURE 10.9 Grand Composite Curve for Process B (Problem 3(b)).

Segment T * [°C] T * [°C] ΔH [kW] T ** [°C] T ** [°C]

start end start end

Sink A1 105 145 280 110 150

Sink A2 95 105 50 100 110

Source A1 95 55 40 90 50

Source A2 55 25 180 50 20

TABLE 10.9 Heat Source and Sink Segments from the GCC for Process A

[Problem 3(c)]

Segment T * [°C] T * [°C] ΔH [kW] T ** [°C] T ** [°C]

start end start end

Sink B1 185 245 240 190 250

Source B1 185 135 100 180 130

Source B2 75 55 40 70 50

TABLE 10.10 Heat Source and Sink Segments from the GCC for Process B

[Problem 3(c)]

Answers to (d) and( e). By analyzing the TSPs (Figure 10.12), one can see that

there is an opportunity to match heat source and heat sink requirements

in the steam temperature interval between 100°C and 180°C. The proposed

steam saturation temperature is in the interval from 117.1°C to 130°C. Within

this interval, the maximum heat recovery through the steam system (equal to

100 kW) is achieved. This results from matching the values for steam generation

and steam use (here both are equal to 100 kW).