Page 269 - Sustainability in the Process Industry Integration and Optimization

P. 269

246 Cha p te r T e n

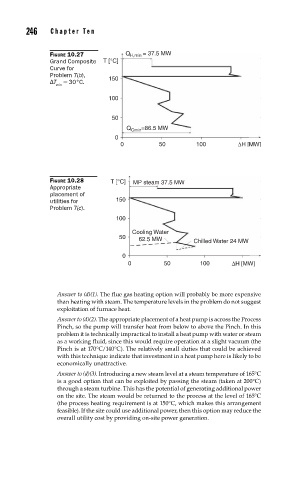

FIGURE 10.27 Q H,min = 37.5 MW

Grand Composite T [°C]

Curve for

Problem 7(b),

ΔT = 30°C. 150

min

100

50

Q Cmin =86.5 MW

0

0 50 100 ΔH [MW]

FIGURE 10.28 T [°C] MP steam 37.5 MW

Appropriate

placement of

utilities for 150

Problem 7(c).

100

Cooling Water

50 62.5 MW Chilled Water 24 MW

0

0 50 100 ΔH [MW]

Answer to (d)(1). The flue gas heating option will probably be more expensive

than heating with steam. The temperature levels in the problem do not suggest

exploitation of furnace heat.

Answer to (d)(2). The appropriate placement of a heat pump is across the Process

Pinch, so the pump will transfer heat from below to above the Pinch. In this

problem it is technically impractical to install a heat pump with water or steam

as a working fluid, since this would require operation at a slight vacuum (the

Pinch is at 170°C/140°C). The relatively small duties that could be achieved

with this technique indicate that investment in a heat pump here is likely to be

economically unattractive.

Answer to (d)(3). Introducing a new steam level at a steam temperature of 165°C

is a good option that can be exploited by passing the steam (taken at 200°C)

through a steam turbine. This has the potential of generating additional power

on the site. The steam would be returned to the process at the level of 165°C

(the process heating requirement is at 150°C, which makes this arrangement

feasible). If the site could use additional power, then this option may reduce the

overall utility cost by providing on-site power generation.